I love it when the weather is warm and I can open the big garage door to the shop. Fresh air, my fan blows dust out, and I can see a passerby now and then. Once in a while someone drops in to chat.

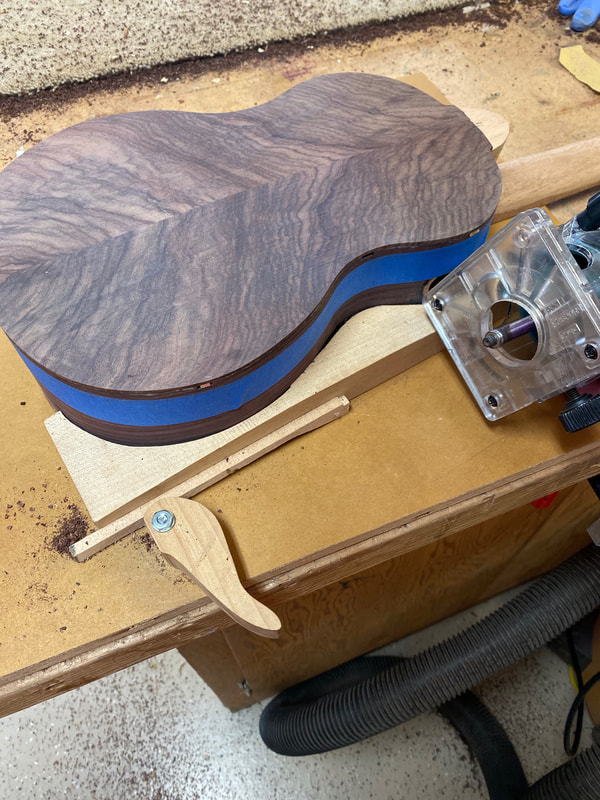

The backs are on, Now to trim the edges of both back and soundboard flush with the sides. The router does this quickly. the blue tape is to keep the bitt just that far away from the side so as not to mar it. The finish is done with sand paper.

The sawdust flies everywhere, wear a mask and get the shop vac ready, but worse is yet to come.

All three ukes trimmed and sanded, I took a little break to trace patterns for peg head plates on this wonderful spalted maple. I will take it to my friend Kurt at Bay engraving who, with his laser machine, will cut out the grooves for the big g that goes on all my ukes. And you thought I did that by hand!

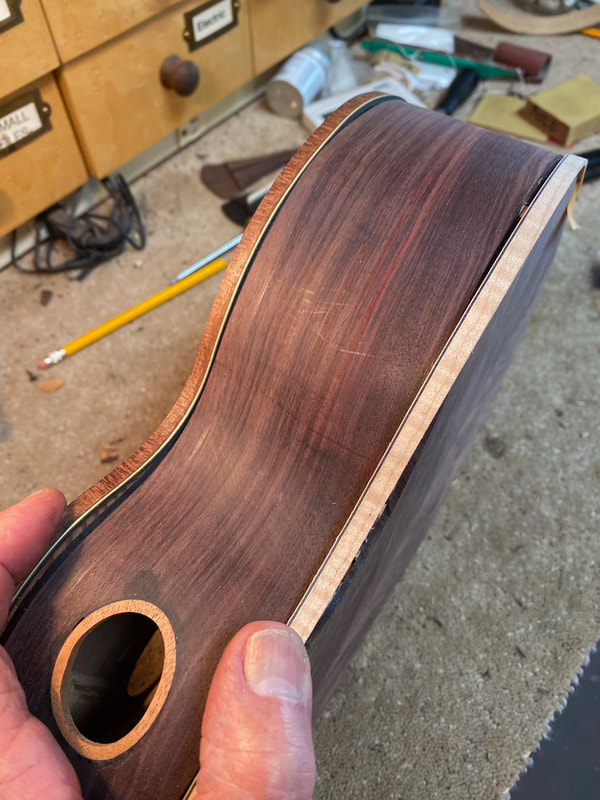

Now for the tough job. With the router set up like this I will cut the slots all around the ukes that will receive the bindings. This is a delicate and dusty job. Always scary as you could ruin a ukulele if it went wrong,

But all went well and they are now almost ready for the bindings, Just a little prep work to do where the bindings enter the neck.

The router can't get to this piece. Got to do it the old fashioned way.

But now they are ready. The bindings go on tomorrow. Which do you like best?