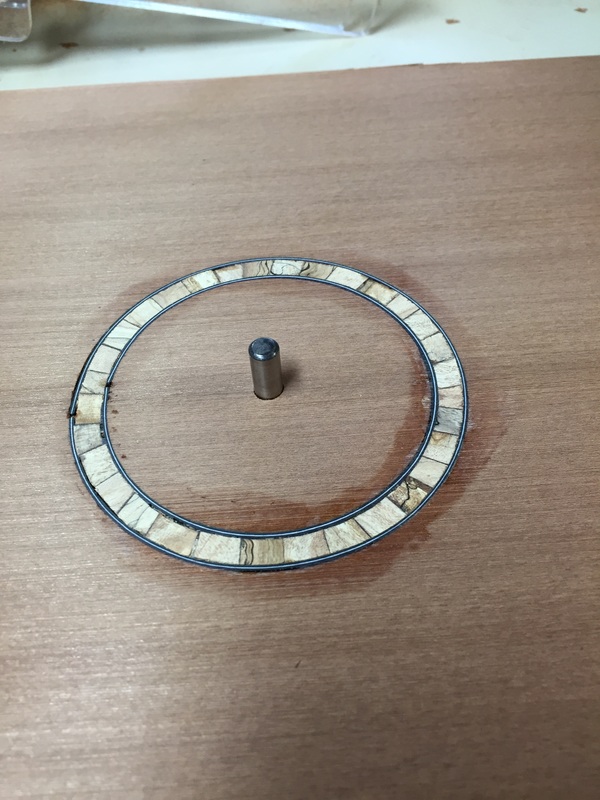

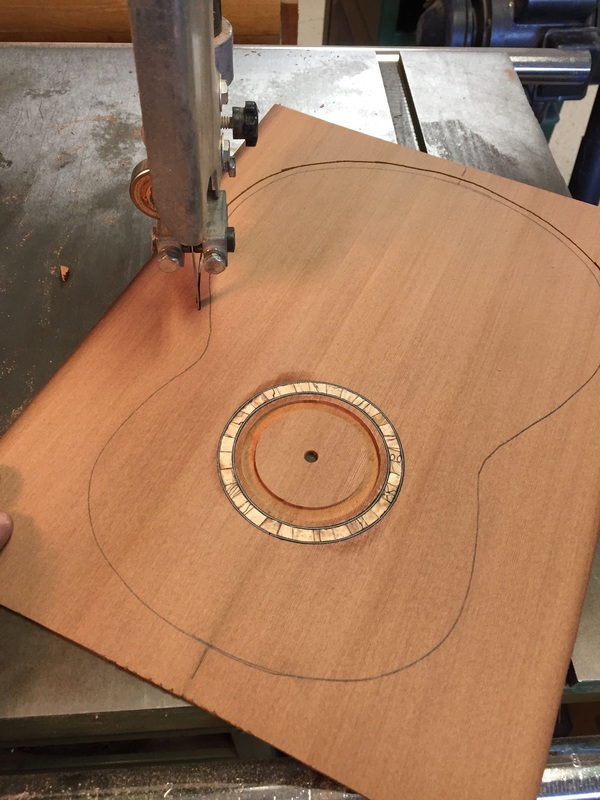

| Now that the rosette is installed and sanded flat it is time to cut out the sound hole. This hole wants to have a radius of 1 1/4 inches. I will cut the hole with the router and a downward spiral bit. I don't want to go all the way through to the work board underneath Here is the cut. With a sharp bit you are able to cut a quite thin rim around the sound hole without tearing out the wood. I think I will now cut out the shape of the top. Makes it a little easier to run through the thickness sander. Here is the completed top, I ran it through the thickness sander cleaning up the shellac stains around the rosette and taking it down perfectly flat, then turned it over and sanded off the back freeing the sound hole and thinning the top to .080. Then I laid out the pencil markings for the bracing that will be glued to this top. Looking good so far. | so I set the bit to cut to a depth of .095. I know my soundboard is thicker than that. I will be sanding the soundboard down to .o80 so the hole will be freed after I have sanded the back down to .o95, then I will continue sanding the back to the desired thickness The bandsaw does a nice job of cutting this thin Redwood without ripping or tearing it. You want a pretty sharp blade. Remember to cut about a quarter inch outside of the pencil line. And here are all three of the soundboards with rosettes, all cleaned up and thinned down to their final thickness. They are sanded to 180 grit so I will have to do very little finish sanding on the tops in the final stages. It is always a bit of a relief to get to this stage because there are so many ways to mess up a top and ruin that lovely Redwood. Next stage is bracing. |

I got talked into turning a bowl for the local Festival of Music Auction, so wearied of working on ukes I loaded up the lathe with this big American Elm blank that I had turned wet several years ago. It has been drying and waiting to be finished. Tough wood, Huge bowl, Messy and hard work but I got this far before quitting for the afternoon.

Bowl turning is lots of fun when the wood is wet. When it is dry like this it is a lot of work, I will peck away at it as the mood strikes.

Bowl turning is lots of fun when the wood is wet. When it is dry like this it is a lot of work, I will peck away at it as the mood strikes.

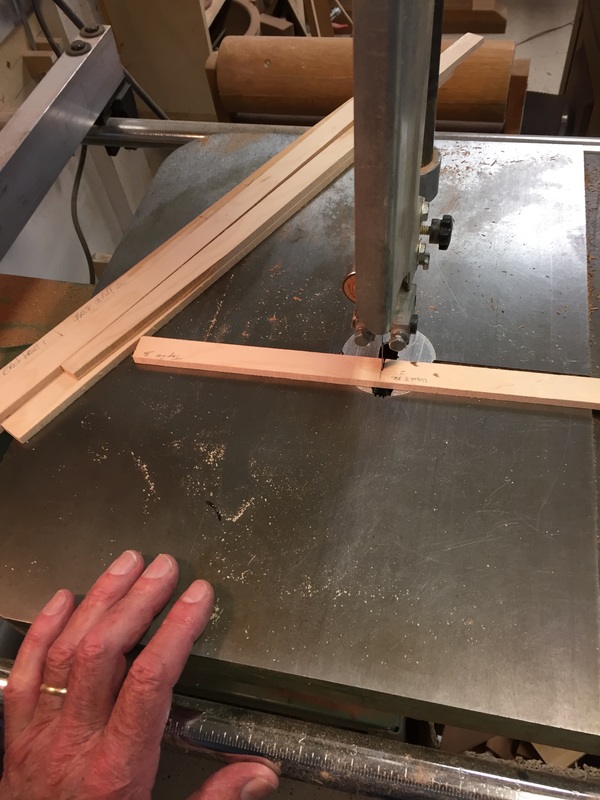

| Went to visit a sick friend for an hour and on my return had time to rip up some spruce bracing and get started on the next stage. Here I am cutting them all to length After dinner, back to the workshop to saw out the shapes on the bandsaw and begin the whittling. Got this many done and ready to be sanded. I kind of enjoy the whittling, This is beautiful tight grained Sitka Spruce that cuts straight and true. A joy to work with. | Next, each brace and tone bar must have its shape drawn in pencil ready for the bandsaw, and then the final shaping with Exacto carving blade, and final sanding. Three tenors takes 27 braces and tone bars. of various sizes and shapes |