Today I glued on the peg head plate, faired and sanded it.

Here is the clamping technique. Note the three little pieces of wood where the nut will be. That is my method of spacing the plate properly. One of those pieces of wood will remain.

Out of the clamps, ready to trim the length of the bison bone nut with the jeweler's saw.

In the vise, I am fairing the edges of the new plate with a fine rasp.

Now with a hand drill I carefully drill the tuner holes with a bitt large enough to allow the tapered reamer to enter. A hand drill is much less likely to punch out the back of the peg head. Not as aggressive as an electric drill.

While I am at it I enlarge the holes about 80 % of their eventual size.

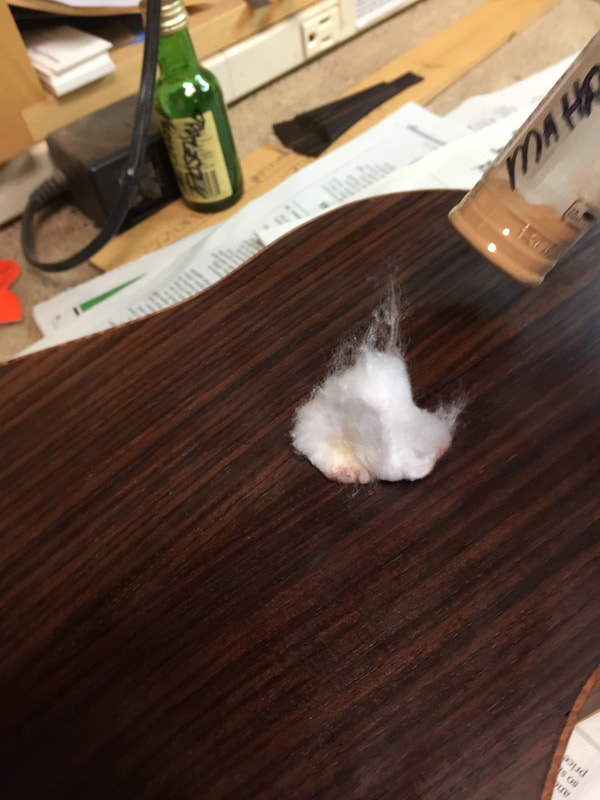

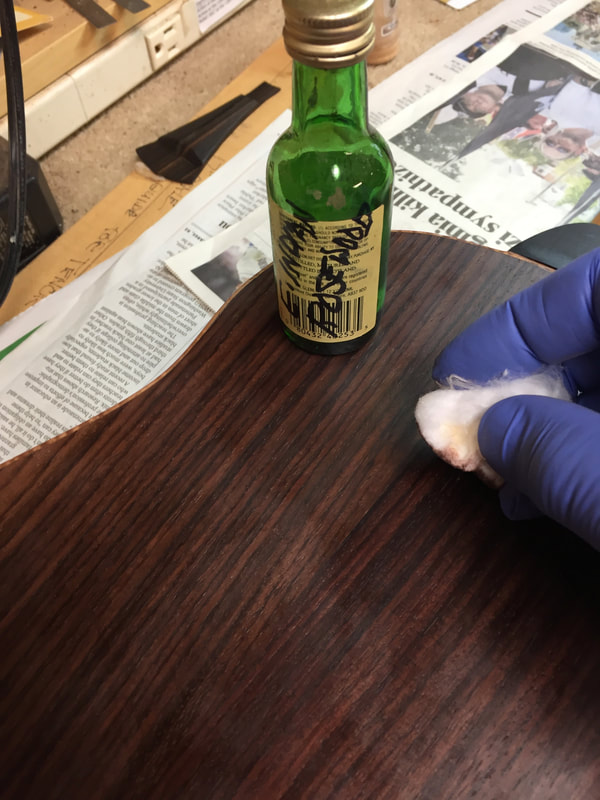

Now it is time to fill the pores on the rosewood and the mahogany neck. I will use the pore fill method suggested by Robbie O'Brien at the Guild of American Luthiers convention I recently attended. Very simple, Use fine sawdust of the same wood, rub it in with a cotton ball loaded with a small amount of dilute shellac, The saw dust fills the pores and the shellac seals it in.

I collect a little sawdust in a tiny booze bottle, punch a few holes in its metal cap, and use it like a salt shaker. Shake a little sawdust over the wood, a few drops of 1 lb cut shellac on the cotton ball, and start rubbing.

The shellac dries in just minutes, then put on a second coat and when that is dry, sand lightly with 400 grit paper. Important!, don't wipe off the saw dust. Go right back in with a cotton ball and shellac and rub that sawdust into the pores as well. Do that twice and your pores will be filled. Just takes a few minutes and you will be ready to start the French Polish.