Luthiers are fond of telling folks how much time they spend correcting their mistakes. I made a big goof the other day on a pretty Redwood tone board-heres the story.

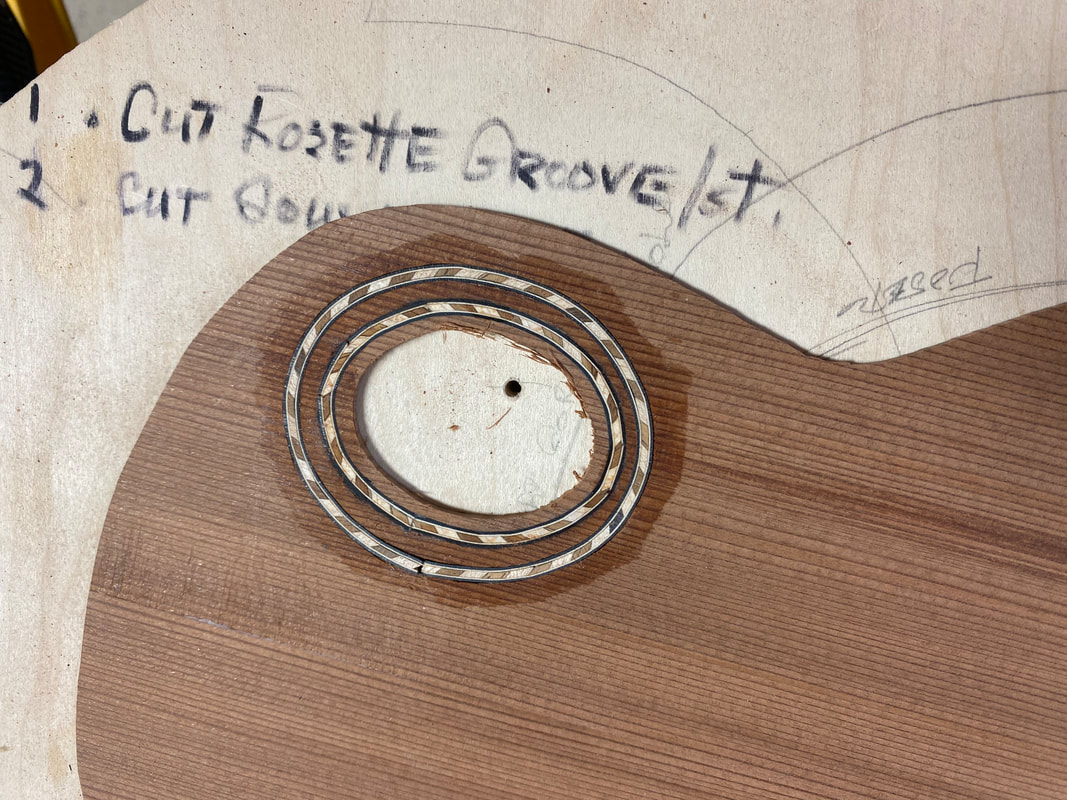

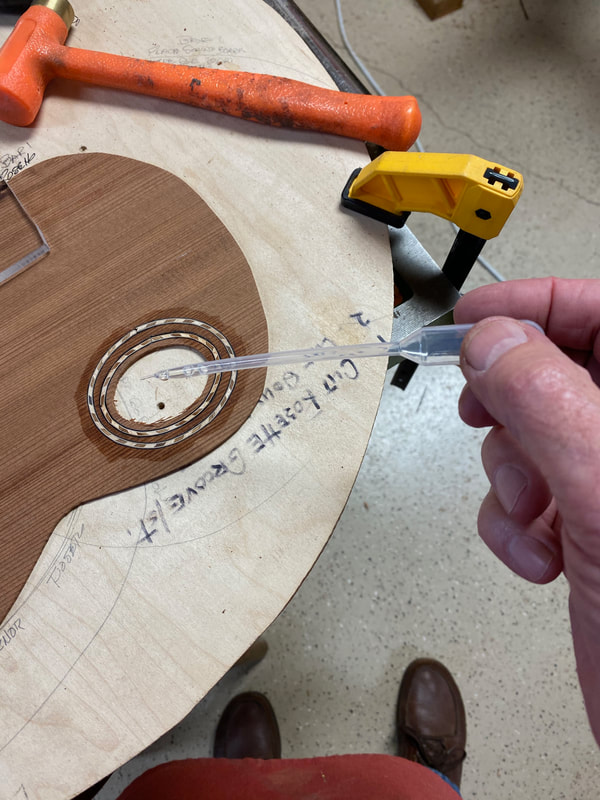

Installing the decorative ring around the oval sound hole begins with cutting a larger oval groove with a router. The router guide follows around an oval hole cut in a heavy piece of lucite seen here. Notice that there are three different sized holes for a variety of instruments and purposes. I got careless and chose the wrong one.

With the groove cut successfully I heated up the Hot Pipe and bent the purfling called "Rope" and carefully put it in the groove, glueing it down securely with super glue. Then I sanded the soundboard down to its final thin .080 thickness, and pleased with myself, cut the sound hole out and sanded it into an oval. BUT SOMETHING DIDNT LOOK RIGHT. THE HOLE SEEMED TOO SMALL. Then it dawned on me- I had used the wrong hole in the template. the hole was too small.

The only choice was to try to cut the larger groove in the now very thin wood hoping it was still thick enough to accept the new rosette. The next morning I did it, Cut the groove, bent and installed the new Rosette, glued it in with super glue and hand sanded it level. Now all there was to do was cut away the first rosette and fair the hole to the larger rosette.

The vertical sander proved its worth as i began to grind away the unwanted Rope.

Carefully sanding it away and back to the proper sized hole.

And finally it is done, An excellent recovery from a careless error. The stain is caused by a coating of french polish shellac used to seal the wood. It will disappear with a bit of sanding and the final finish. SUCCESS!!!