I FIND THAT I usually stall a while before facing the task of routing out the grooves for the binding and purfling around the edges of the uke. This procedure holds the risk of destroying all the work you have put into the boxed up instruments. Today I awoke with courage in my heart and took on the challenge. Now with the daunting task successfully completed, I am enjoying a drink and anticipating Marya's corm beef and cabbage dinner cooking in the oven and smelling mighty good. It was a good day to bite the bullet

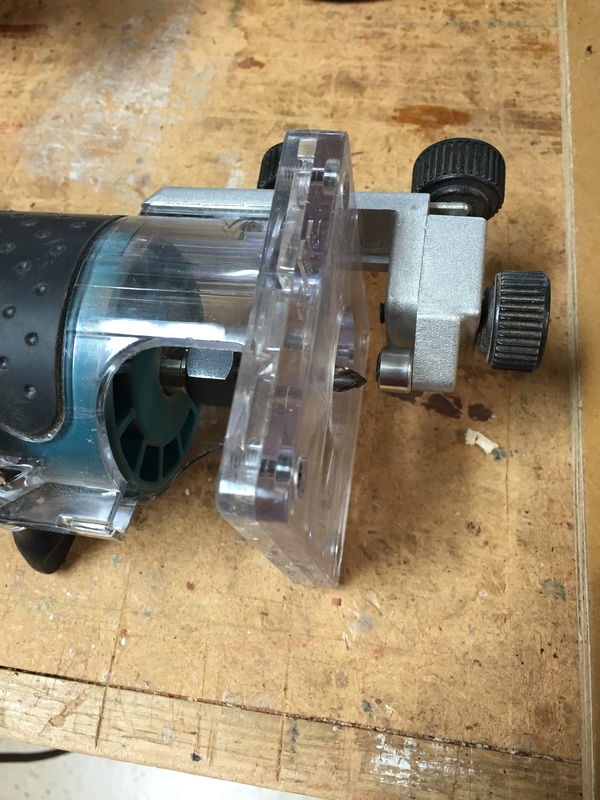

Here's the tool, a small router called a laminate cutter. It is set up with a down spiral bit and a detachable attachment that rolls you around the edge of the instrument. You carefully set the router to cut the groove just a little shallower than the binding. With the binding standing proud you can sand it down flush to the side,

The challenge is to set the router properly to cut, first, the big groove for the binding, Then you must reset it to cut the much smaller little groove to accept the black/white/black purfling that I like to accent the binding with.

Here is the finished routing ready for installation of binding and purfling.

Here is the finished routing ready for installation of binding and purfling.

Thank goodness for shop vacuums. This routing makes an incredible mess, flinging chips every which way, but the vacuum picks it up quickly.

To do this kind of delicate routing you must be able to hold the instrument solidly. This clamping hold jig I made years ago doe's the job very nicely. I simply clamp it to the work table when I need it. The cam clamp holds the uke and it is ready to be worked on. When I no longer need it, it is unclamped and replaced by the vice or something else.