Taking the router to the newly boxed body to cut the grooves for the binding is the most perilous part of the build. A mistake could be disastrous. Fortunately the day went well, Perfect cuts. The rest is easy.

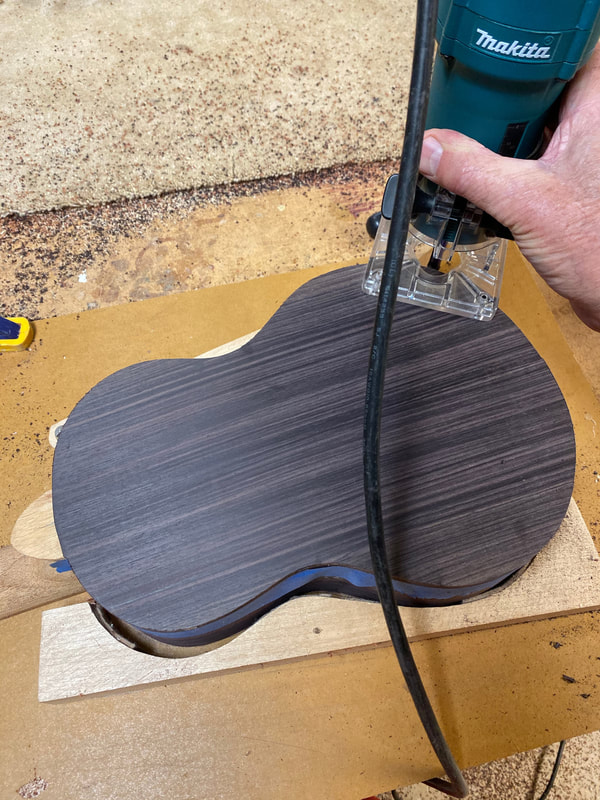

First the edges of both back and top must be trimmed flush. The tape is to cause the flush cutter bit to leave the edge a little proud and not cut any of the side. The tape thin edge will be sanded flush to the side by hand.

The router follows the shape of the side because of the small roller bearing at the end of the cutter bit. The roller rolls on the blue tape thus cutting a tapes width away from the side.

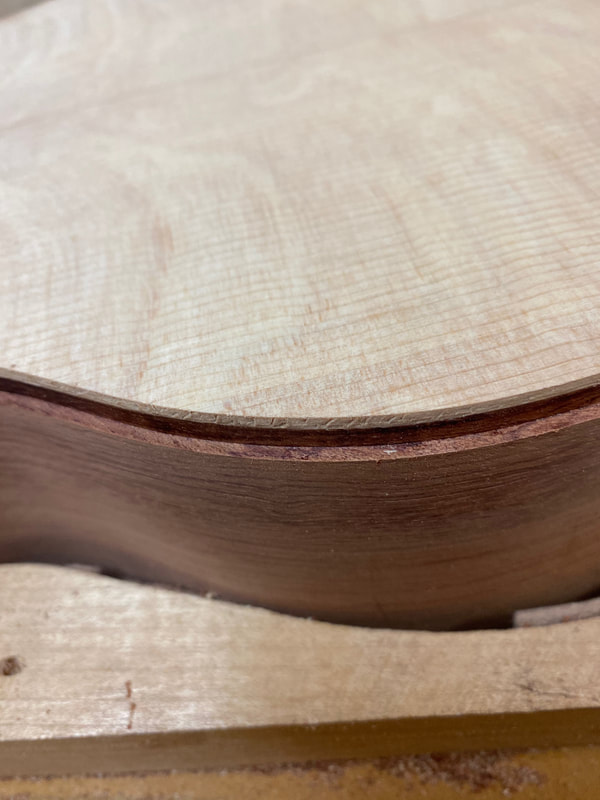

The scary part is cutting this big groove that the binding will be glued into. Concentration and a steady hand are required.

This is a deep cut and splitting off chunks of wood is always a possibility. I do it in several passes cutting a little bit at a time. Always a relief when it is done successfully.

This is also a messy job that throws sawdust all over the work bench and floor. You want to wear eye, ear and lung protection.

The final cut is the space for the End Piece. It will be fitted and glued in after the binding is glued on. Now the final fun can begin.