Today we attached the butt block and bent the sides. Always an exciting step forward.

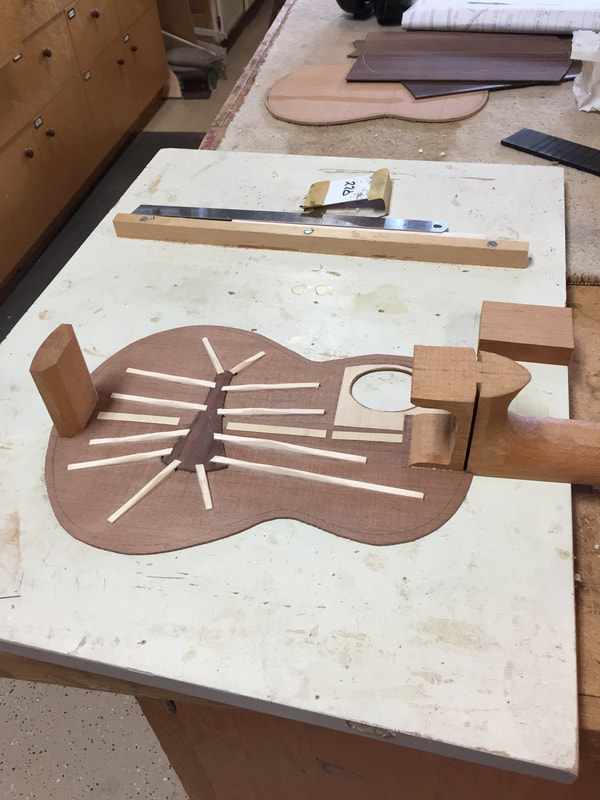

Here is the butt block, now glued in place and ready to accept the sides.

And here are the sides, sanded down to ,071 or .072 and all sized , marked and ready to bend. Note that I indicate which is the head, which is the tail, which is the flat side etc. It can get very confusing to bend sides and proper notation really helps.

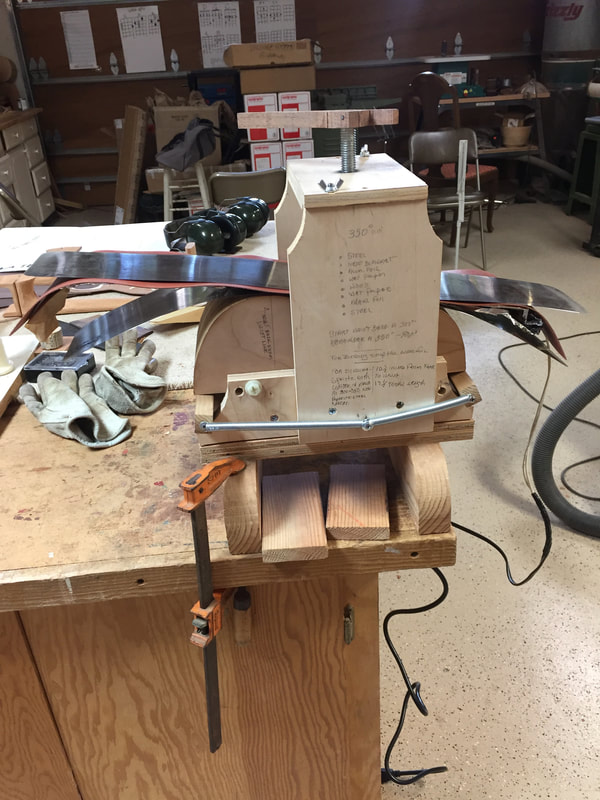

Now the bender replaces the vise on the work bench. Here you see it loaded with the bending sandwich. first, a stainless steel bending steel. Then the side wrapped first in wet paper and encased in a tinfoil cover. On top of that goes the heat blanket, and then a final sheet of bending steel. Now for the heat.

And this is how you control the heat. A simple router speed control which varies the electrical input into the heat blanket. lets turn it on and see what happens.

The head is bent, Didn't hear any cracks.

And so is the tail, always an easier bend. I am hopeful we got a good bend.

Once the bend is made the heat is turned off and you leave it to cool down to at least 100. It had reached just above 350, now it is cooling.

then you can take it out of the press. This is looking good so far. If you have a break it is visible through the tin foil.

Success! a good bend. A few minutes later the second side was bent, and so tomorrow #100 will get it's sides attached.