The parts are mostly made, now the challenge is to but three all together to make a ukulele. Here is where it begins.

the sides must be bent, U di ut ib the hot pipe. This is simply a piece of iron pipe with a soldering iron inside it. It gets up to 260 degrees, Hot enough to do the job. On the work table behind you can see sides that have been bent cooling and drying in molds.

This nice bend of tiger stripe maple will be left in the mold overnight to set it shape.

Next morning this nice set of sides is ready to install. First you must trim the ends a bit to be sure that it fits properly.

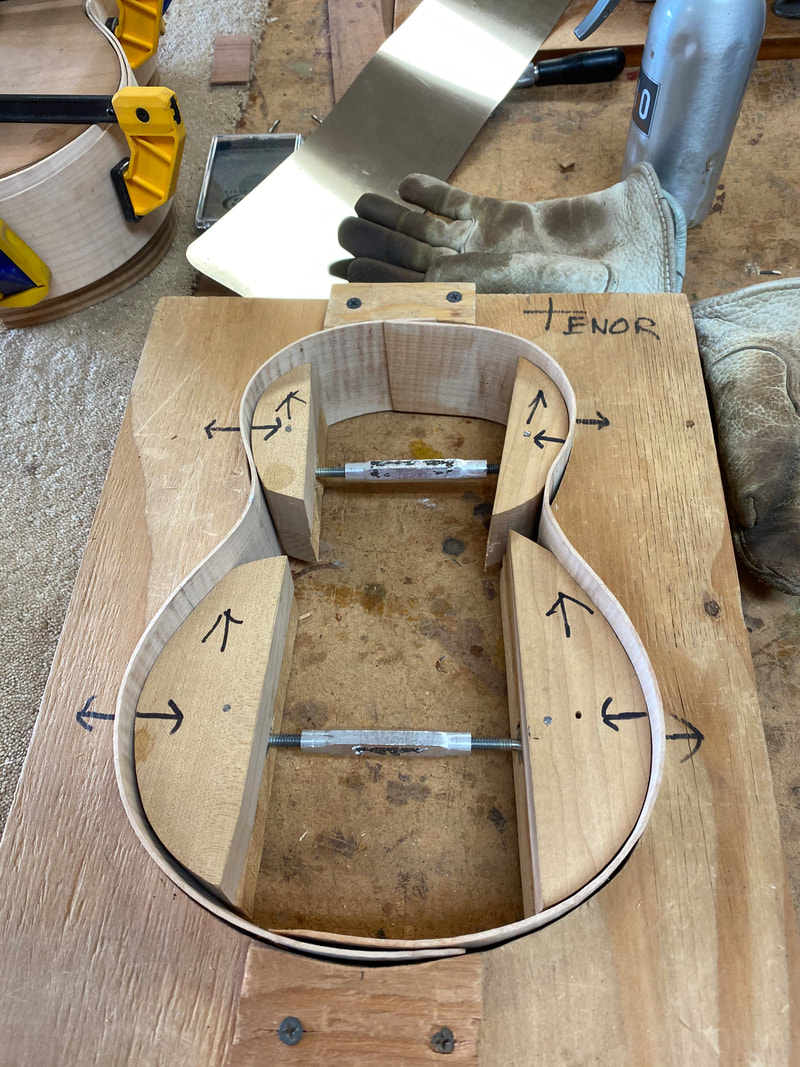

Here it is trimmed to fit and glued and clamped.

Now both 142 and 143 have their sides attached. Both sides fit nicely, These promise to be nice ukuleles