Yesterday I went to my storage locker full of wood and found that big chunk of basswood that I recalled secreting away several years ago.

I sawed the entire thin into 5/8ths thick slats on the band saw, and now I am reducing those slats down to the basic shape of the tent alone. I am using the band saw, rather than the table saw to reduce wastage of the saw kerf.

It took about three hours at the bandsaw to reduce that big chunk to little strips but I am making these things for lots of future jobs. Might as well do it all at one time. After they are all cut, I run them through the thickness sander and smooth them all down to exactly the same thickness. They must all fit in my slot cutting jig.

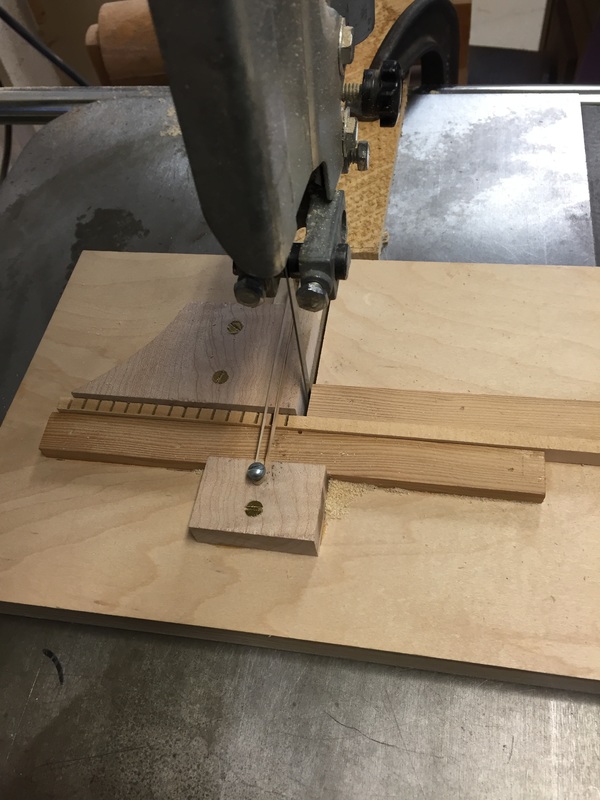

Here is a tentalone going through the slot cutter. A little boxwood indexing point powered by those two rubber bands slides into the last cut slot and stops the workpiece. Then the sled is pushed forward and another slot cut. finally the slotted workpiece is shaved to an angle and sanded in another operation. Then finally it is ready to be glued to the instrument.

And here they are, all with tentalones installed.

Now the backs are sanded smooth and even on the big sanding disk sitting on the table saw. It is very important to measure carefully here so that your instrument will have equally high sides. You don't want a lop sided uke.

You also seek a flat glueing surface for the back that will be glued on as soon as the side sound port has been installed.

You also seek a flat glueing surface for the back that will be glued on as soon as the side sound port has been installed.