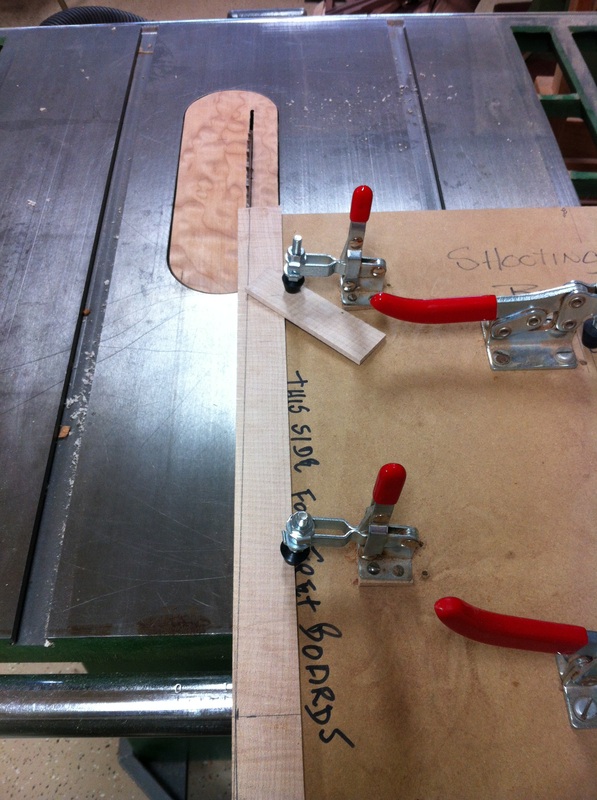

I BEGAN THIS pinecone build by working on the sides. They curve as one piece around the instrument and are only 1 1/4 inch high at the butt center and they taper to 1 inch at the neck. The slope must be cut into the sides initially. I cut the taper on the table saw using a sled with clamps mounted on it. because this sled is used for tapering fret boards and larger sides I must use a little block of wood to successfully taper these extremely thin sides.

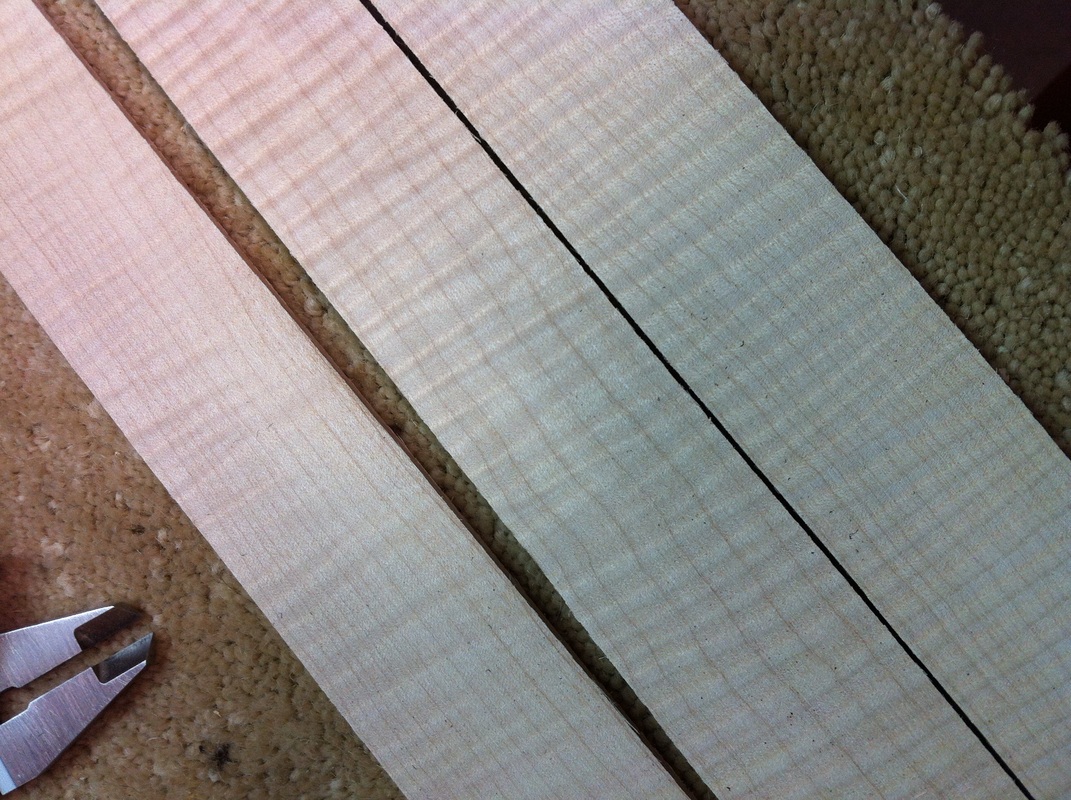

After trimming them to the proper taper they must be thinned to bending thickness. I use the thickness sander. Never use a planer on this highly figured maple as it will just tear it up. You must sand it down.

Here it goes through the sander, pass after pass until it is just the right thickness.

Here they are, tapered and thinned to bending thickness Just look at the "tiger stripe" figure in that maple. It is just a joy to work with marvelous wood like this. Next come the tops of Spruce, Then must be thinned down to .80, then braced and the sound hole drilled. Hope I can get to that tomorrow.