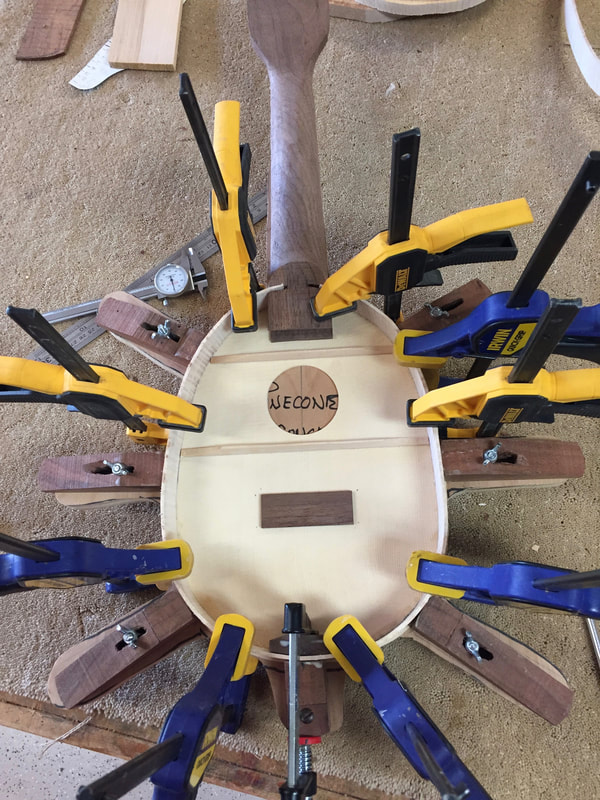

before we can progress further I had to glue on the butt plates and the bridge patch.

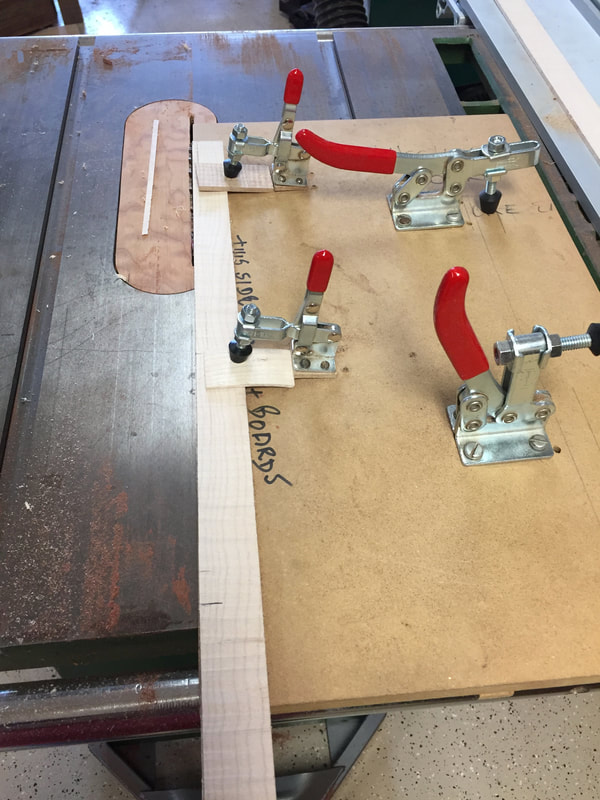

While the glue was drying, I had time to saw the angle in the sides. the uke is a little thicker in the rear than at the front of the body, and that is accomplished by sawing a taper towards both ends. the center of the side piece will be at the very bottom of the instrument.

Then I took the sides to the thickness sander and sanded them down to proper thickness before beginning the bend. Before bending I ran them under warm water in the workshop sink.

'this is an easy bend with the heat blanket turned up to 300 degrees and bending over the concert form. Now we will let them cool and set the shape.

It is going to fit

So lets glue it down, clamp it hard, and even put the tentalones in.