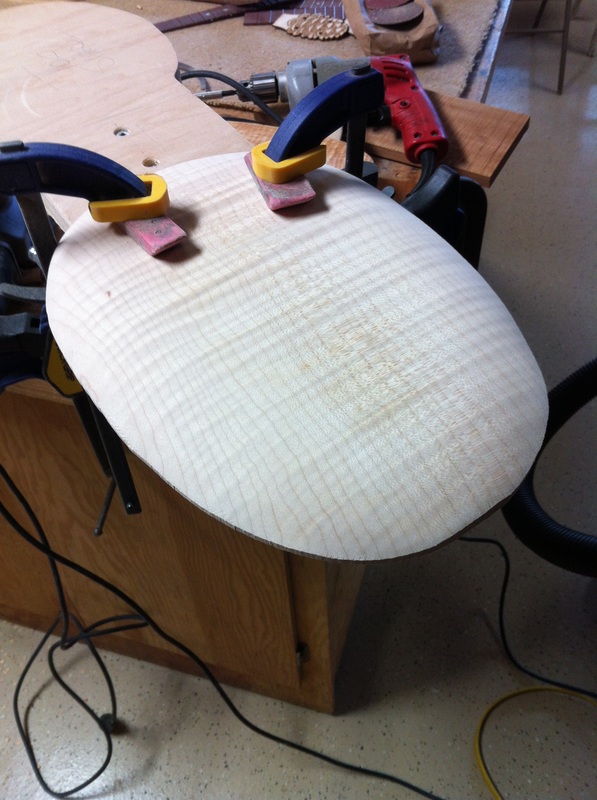

| 1. Now that the concave side of this back is done I can turn it over, clamp it down and take the orbital sander to the convex back perfecting the curve and taking it down to good viable wood . thats the last of the shaping until the back is finally glued on and fitted. Final sanding is done then 3. Here is the underside. I cleaned up around the edges with a Dremel tool fitted with a grinding cutter. | 2. Here the back is completely sanded and ready to be glued to the neck top and sides already assembled. Then the final sanding will be done. 4. The back is just a little thicker than 1/8th of an inch. You can tell by using this woodturners gauge. One end goes over the wooden back, clamp it tight and look at the size of the gap at the free end. That is your thickness. Just right! now two more of these to go and it will be glueing time. |

| Griffin Ukuleles |

|