It has been a delight to hole up in the workshop during this winter weather. The four tenors are coming along well.

Here is the way the tentalones are glued to the lower rim of the sides. Good old fashioned clothes pins beefed up with rubber bands to increase the squeeze.

I takes an amazing amount of these tentalones to complete a ukes. I make them myself and seems that I am always running out of them

Here is the completed goal. Once I get the side sound port installed, this ukulele is ready for its back.

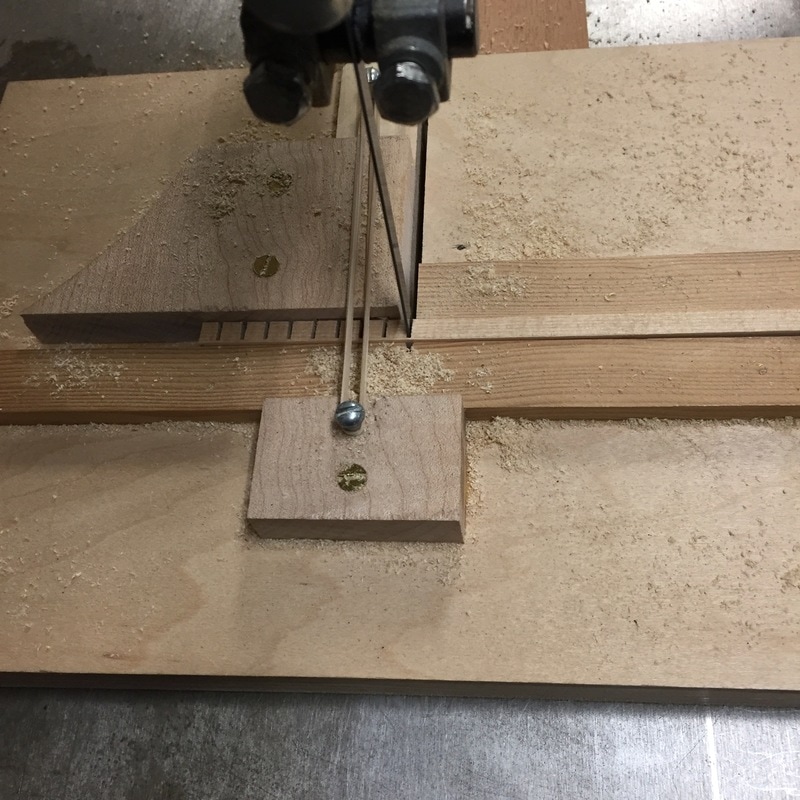

This is how the tentalones are made. Long strips of basswood are let through this jig on the band saw. A little rubber band powered bolt stops it so the next cut can be made at the proper place. A fun little invention that works remarkably well.

Before the back can attached the side sound ports must be installed. The hole is cut and then shaped with a grinder attached to the Dremel tool.

The side port ring is carefully fitted. It takes some cautious and careful time with the little Dremel grinder. The rings were made for me by Rick Miller on his CNC machine. I have a lot of them, so if you need one give me a call or an email.

Once you have the ring fitted into the hole gap filling superglue does the job

And now the next step will be to carve that ring down flush both inside and out. Won't be long before this use can be boxed up.