I had a fun and productive afternoon in the workshop today. Some new experiences and some learning.

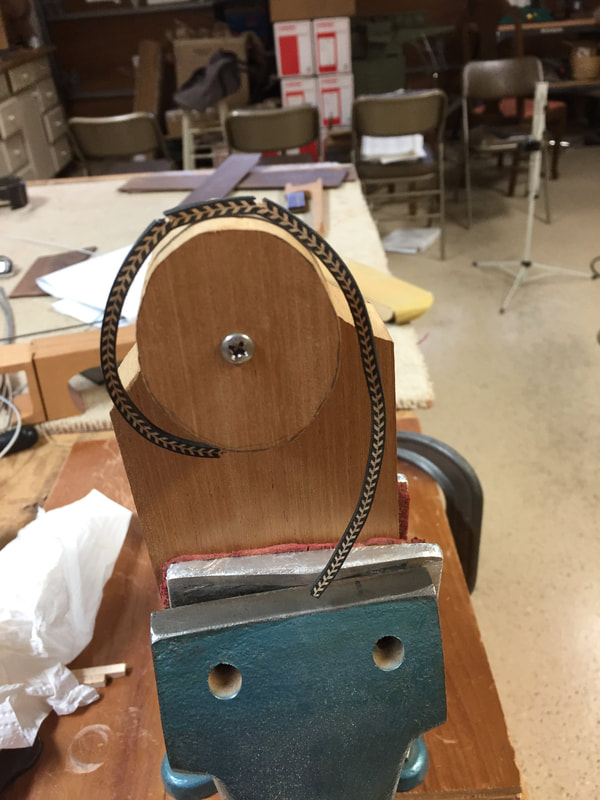

The first challenge was bending fancy purfling to fit the tight oval around the Kasha sound hole. I just received some purfling from Luthiers Mercantile Inc. and I wanted to bend some of it around the oval. I made this form to bend it around.

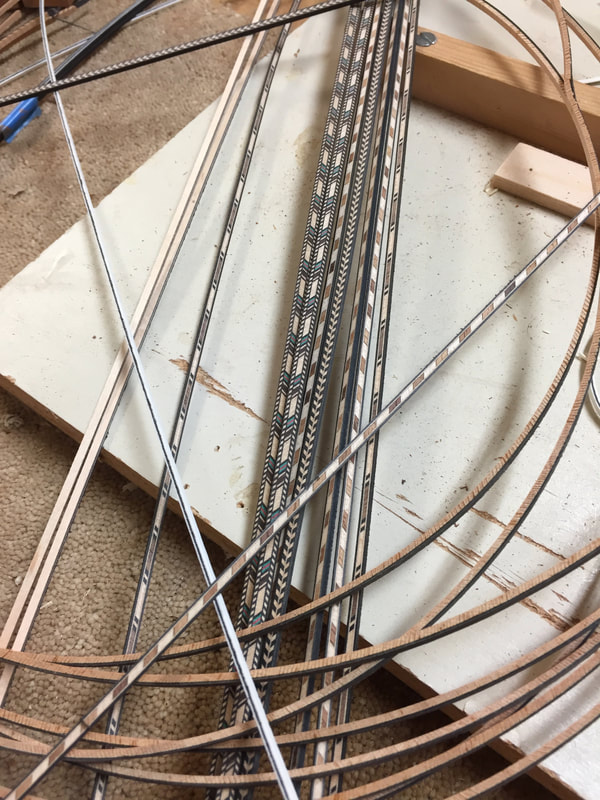

Here is some of the beautiful material I bought. But now how do you bend it into a tight oval or, around the shape of the instrument.

The answer is HEAT. I discovered that with a few passes of hot air from the heat gun this purfling will soften-bend- and hold its shape as it cools. It is not easy but it is doable, so I tried it on several different purflings I had bought. here is some regular white/black/white. Easy to bend, but I wanted something prettier.

I also learned that my first bending form needed improvement. I needed to bend all of the way around the oval, so I cut out the oval and screwed it onto the backing piece. Now I had the freedom to bend all the way around.

Then I tried this purfling, that I really like. I was able to bend it but found it a bit too wide for the groove that I had cut in the soundboard. I could have made this work despite the broken pieces. I was just too wide.

I almost forgot. Before you put super glue into a groove you must seal off the wood with a coating of shellac. Super glue stains wood and it is so thin that it travels through the grain very quickly. I have put a coating of shellac into the groove that will receive the purfling, If I can successfully bend it.

| I was able to bend this purfling and get in place, then with medium thick, gap filling superglue I set it in place. Now for the finishing touches. |

Here are some of the other possibilities for future instruments.

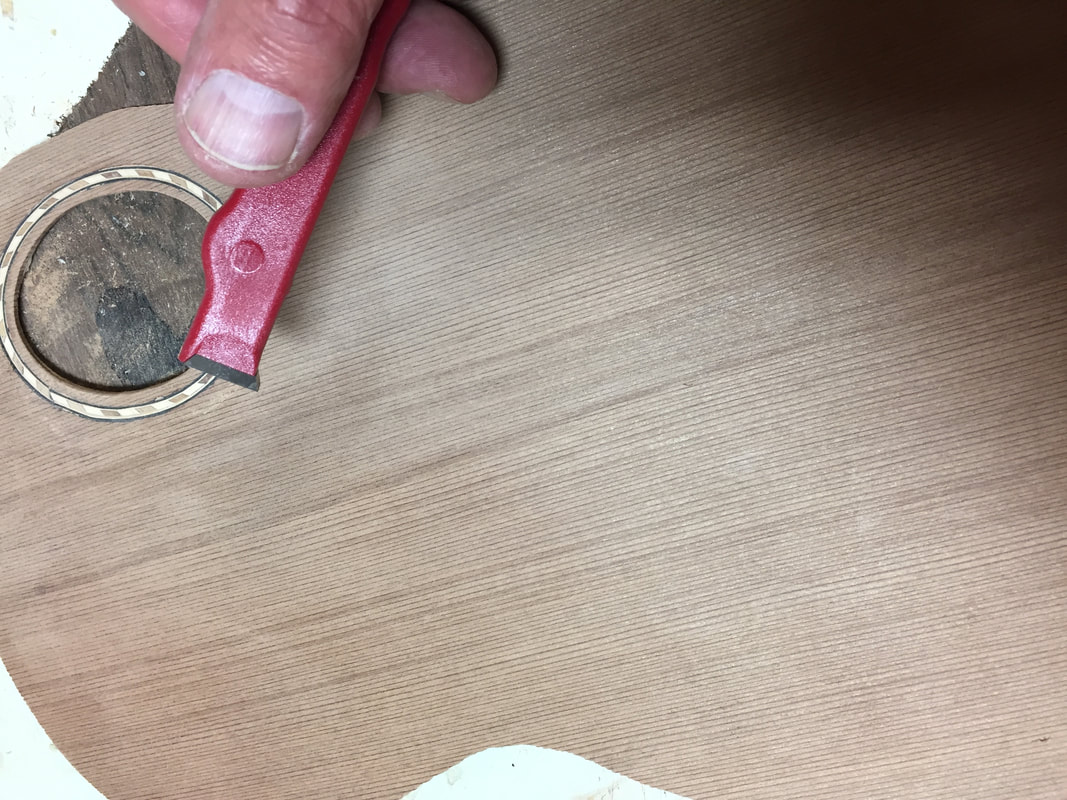

Now, with this delicate little scraper, I scrape the purfling down to level. It is looking pretty good.

And here it is, the finished product, Not perfect, but not bad for a first try. work on the neck also made progress, Show you that tomorrow.