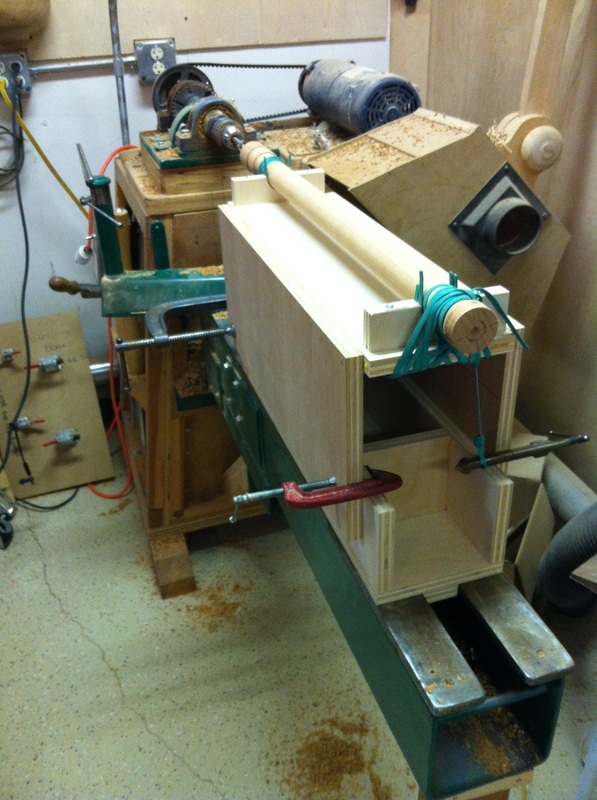

SO FAR SO GOOD; My contraption designed to drill a straight hole up the round stalk of the music stand is working. Let me introduce you to my modest invention, an adjustable device that slides on the bed of my wood lathe.

You can see that it slides on the lathe bed held in a straight line by the protrusion that extends into the gap of the bed. It can only travel straight. I placed the music stand rod back into the lathe and built this plywood box under it. Notice that it is really two boxes, one fitting into the other. It is adjustable in height and held at the desired height by shop clamps. I then fitted circular holders cut to size on the band saw and bolted to the top of the device. Raised the device to fit snuggly into the "Rod" and clamped it in place. Then I put a couple pieces of rubber in the circular cavity to retard spinning of the "Rod" during the drilling process. Then I "clamped" the rod down tight with the big green rubber bands. Now the "rod" is exactly in place held tightly by the rubber bands and I was able to remove the lathe bit and replace it with a chuck holding a 3/4 inch Forster drill bit.

| Here it is perfectly positioned to drill a center hole. The chuck has replaced the normal lathe bit, the "rod "is held firmly by the rubber bands It takes a lot of pressure to make a Forstner bit cut into end grain. I found that the pressure exerted by this screw was essential to making this cut work. Every turn of the screw resulted in the sound of wood being cut, and the drill bit dug deeper. | And now it is time to put it to the test. Will a Forstner bit do the job? Will this contraption really work, can I drill a seven inch hole up the center of this piece of hard Cherry wood? Here we go !. Here is the proof; The drill bit is in 2 1/4 inches. straight and true. I am very pleased that I think this is going to work. Tomorrow I will borrow a friends bot extension which hopefully will allow me to carefully drill the remaining 4 1/2 inches that I need to make this work. |