MY FUN NEIGHBOR GEORGE HAS RIGGED UP THIS TREAT FOR THE TRICKERS.

He worked all day to get this rigged up. Sure hope there are lots of little kids at his door tonight.

But before the spooks walk, I had a productive day in the shop. #101 is boxed up, has it's side sound port and is surely going to be ready by Christmas. Here is what happened.

It began with the side sound port. Here is the piece I use to pencil in the location. It is curved to match the curve of the instrument.

Here is where it goes.

But before we put it in there, we need to provide some protection against a split in the side. This is a piece of ebony veneer cut to fit inside the side under the sound port. The grain on the patch runs counter to the grain of the side, thus providing great strength against a split.

I have glued the patch in and clamped it in with this curved caul. Works every time.

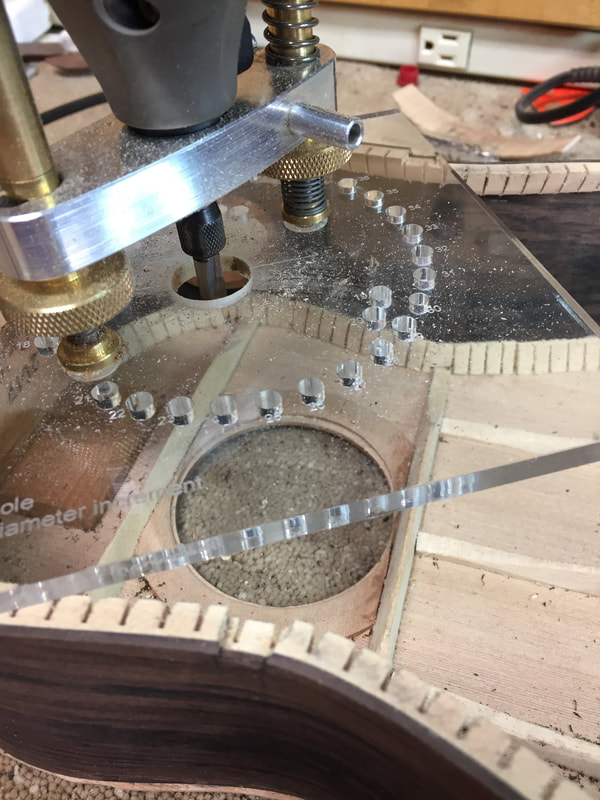

Now that the glue has dried I can drill out the rough shape of the sound port. I do this with a drill bit in a Dremel.

And fair it out with a sanding disk on the Dremel. Careful now. don't get in a rush.

getting close now. Just a little more grinding. Take your time, go slow, test frequently.

And finally fits in. Now for some super glue to lock it in place.

Aw! perfection. Once is is trimmed down a bit and sanded flush it will be perfect.

With the sound port installed I can now box up the instrument. Here I am cutting slots for the cross back braces. Don't be alarmed, these cuts in the sides will be covered up by the binding that will go all around the instrument.

Here it is with the back fitted and clamped as the glue sets. In the morning the clamps will come off and #101 will be well on the way to completion. What kind of binding and purfling do we want to use.?