This old and labor intensive finish has been used for hundreds of years on fine instruments. It provides the thinnest of finishes and so is considered the best finish acoustically. It is really just shellac diluted in alcohol and rubbed on the wood in scores of separate applications.

Here is what you need. A bottle of Everclear 190 proof alcohol and a package of shellac flakes. It also helps to swipe your wife's cooking scale from the kitchen while you prepare your mixture.

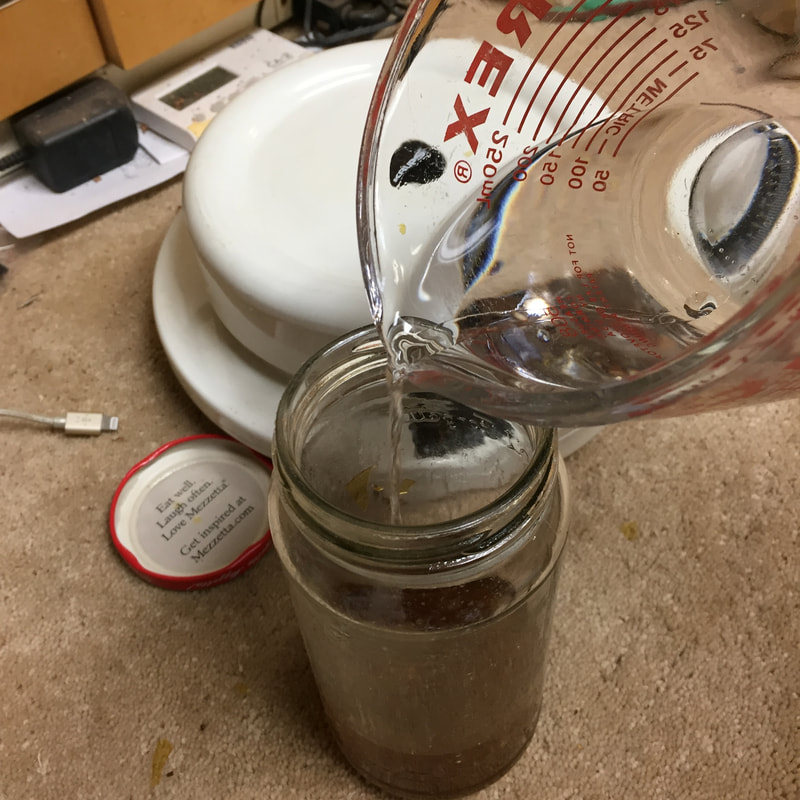

weigh 1 ounce of shellac flakes in the scale and put it into a small glass jar.

The next morning, with refreshed mixture, the second day of finishing began. The wood is just beginning to show a little shine. It takes many applications over a couple of weeks which is why factory instruments have spray on plastic finishes. Way too much labor.

With the finishing in progress it is time to start another build cycle. Today I selected the wood for instruments # 129, a East Indian Rosewood and Redwood tenor going to Australia and #130, a Bubinga and Bear Claw Spruce tenor which will find its home in Seattle.

The first step is joining the pieces. Here, the Redwood soundboard for #129 is in the clamps.