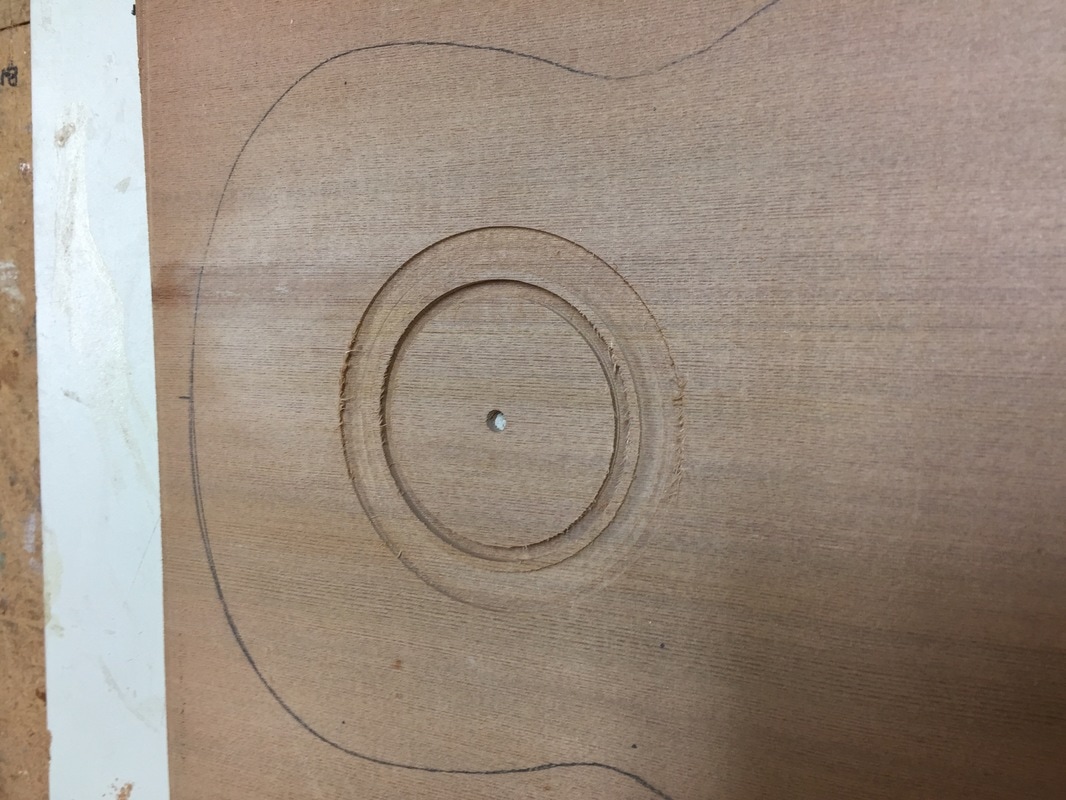

It begins with a 3/16ths hole in the dead center of the sound-hole spot. Yes, I know I am old fashioned using the old hand drill, but it is slow, easy and accurate-and this is an important hole.

Important because it centers not only the sound-hole, but the rosette that I will be putting around the sound hole. Get this wrong and you will need to start over.

Now with the Dremel, a 1/8th inch router bit and the great device that Jon Dale invented, I have cut the Sound-Hole and the channel for the rosette to be glued into.

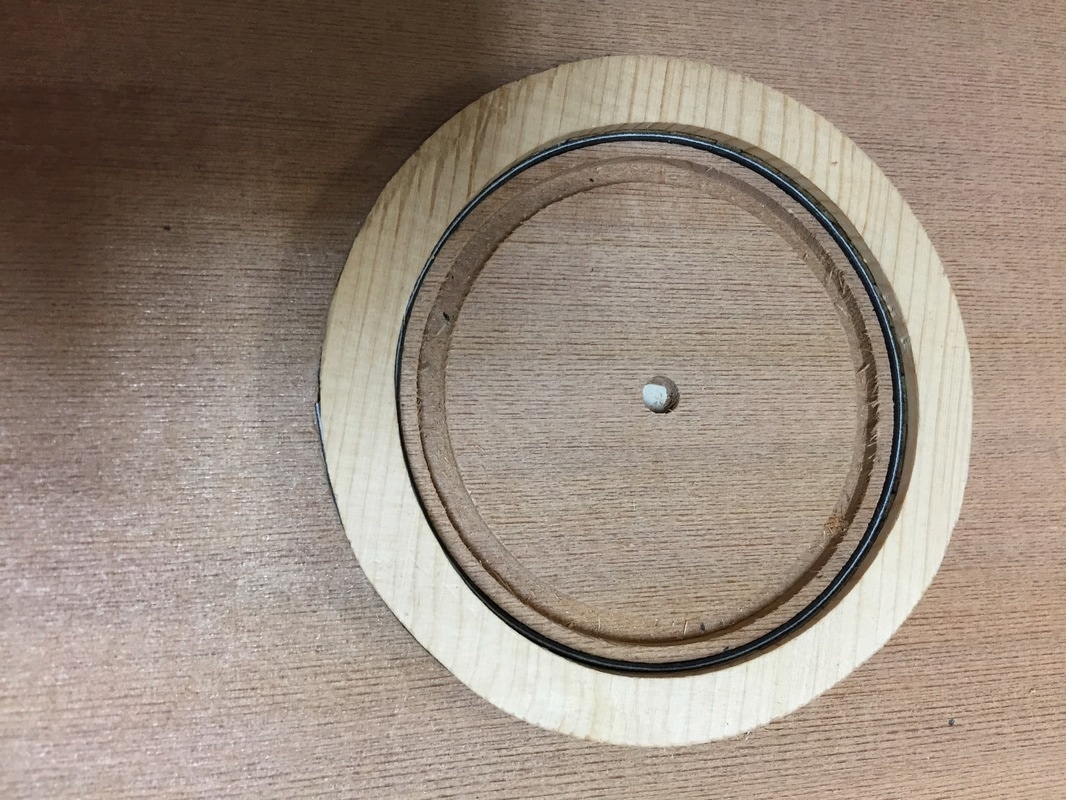

Fortunately, last time I made rosette rings of spalted maple, I made several extras. I will use one of those on this ukulele.

Here the rosette is put into place in its shallow groove and the black/white/black purfling has been inserted both inside and outside the rosette. The fit looks just right. I will apply glue and re-set the pieces in the morning. When the glue has dried this soundboard will be run through the thickness sander until the spruce backing has entirely been sanded away and all is smooth. Then the top will be turned over and sanded to its final thickness and the hole will be open.