Nothing seems more important to the feel of a Uke than the neck. I just finished the rough carving of the neck bringing them to the point where I can attach them to the tops in preparation for attaching the sides. Here is the process.

You must be sure the top or fretboard side is perfectly flat and that the sides where you will saw the slots are at 90 degrees from that top. Then carefully plan where your slot cut must go and carefully mark your cut. Then off to the band saw.

Make sure your band saw blade is at exactly 90 degrees with the table- that is critical. Then you can cut the "side slots" that will receive the front ends of your bent sides. I take a careful two cuts widening the slot so that I can be sure it will accept the sides. I use an old scrap of bent side to be sure the slots are large enough. It is a lot easier to do it now than later when the neck is glued to the top.

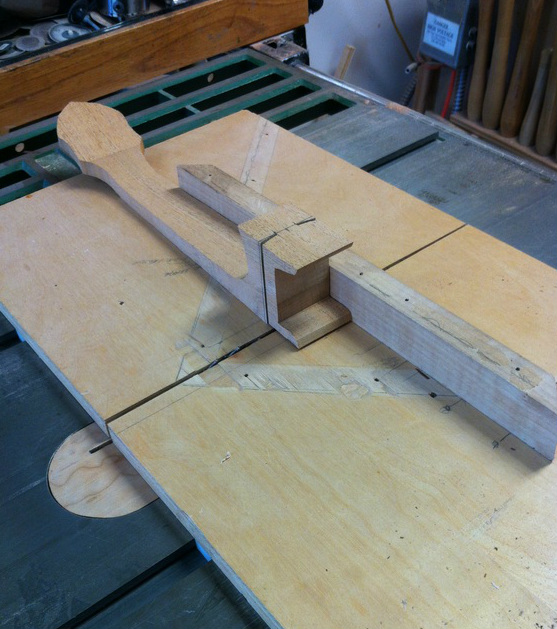

Once the slots are cut it is time to hog out the recess that will accept the top. It must be exactly the depth that the top is thick so test your saw blade height on scraps of wood until you have it perfect. Then with repeated passes of the sled you hog out the recess.

Then with chisels including this perfectly flat chisel you prepare that recess to accept the top.

With slots and recess done, now the carving begins. Draw a few guidelines for yourself, then start to work with curved knives and rasps.

And finally the necks are ready to attach. The final shaping and thinning comes much later just before the finishing begins.