once you have shaped the back to a pleasant roundness it is time to turn it over and hollow it to a thin concave shell.

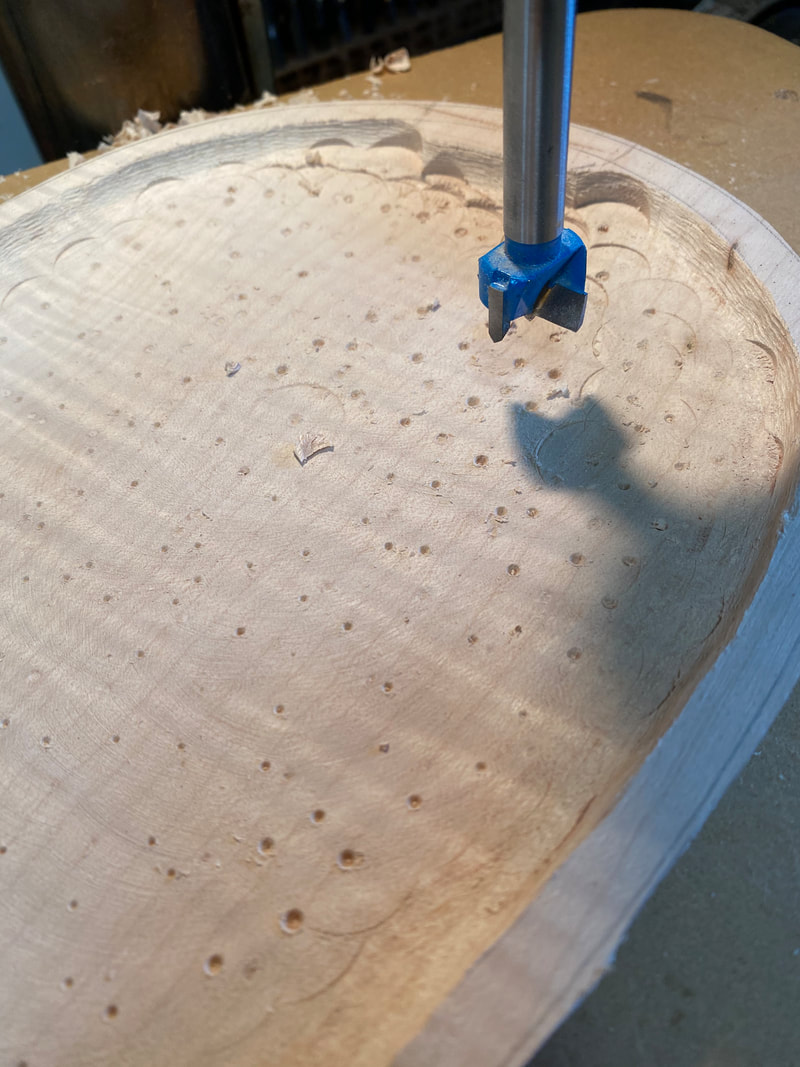

On the drill press Set the tip of this Forstner type drill bitt to stop at just the thickness that you want the back to be. Then hog out the entire back. the bitt will follow the curve you have rasped into the outside. Trim up the edges a bit with a round cutter in the drill press.

Now with a rough sanding disk in the electric drill sand down the surface until the moment the tip marks disappear. Now you know the back is thinned to the desired thickness. This is a dusty job, so set up your shop vac. to suck all that bad stuff away.

A good sharp scraper cleans up the rough spots and improves the edges

And after sanding the glue surface flat with a big piece of sand paper on a flat surface, these Pinecones are ready to box up.

These huge rubber bands are perfect for this clamping job. In the morning I will be fairing up the edges and making these look pretty. Then it is just a matter of carving the necks and making the fretboards.