I FINALLY GOT TO THE BENDING PROCESS for the pinecones I am building. This is really easy bending because the sides are so small. Only one inch wide. The only complexity is that the side is bent as one continuous piece. Here is how I did it.

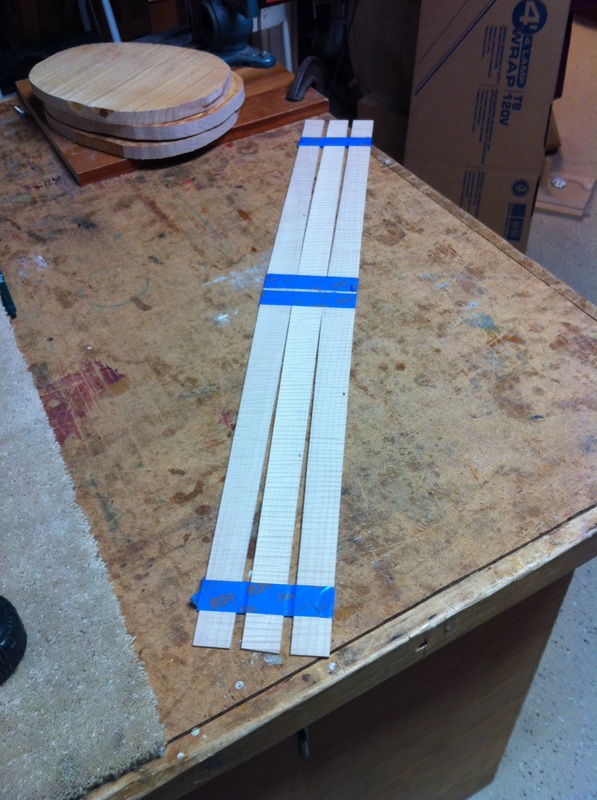

| I taped all three sides together in order to bend them all at once. This blue tape works well for this as it doesn't leave much sticky goo when it gets hot. Mark the center of the sides. That will be the high spot. Once the sides are relaxed and bent around the oval form I apply the additional clamps to hold the position and then turn the bending form over and re-clamp it into the vice with the small end of the egg shape up. We must now bend the sharp bend where the side will go into the neck slots. | Lock the very center of the side pieces onto the mold at the mold center The red heat blanket is then turned on and when the heat gets to about 200 degrees you can start bending the wood. Use a dowel or another piece of wood to push on and very slowly you will feel the wood begin to give in. Let the bent sides cool and set up for twenty minutes. Then take them out of the mold. It is easier to shape them one at a time over the sharp bend. I just leave the heat blanket draped over the mold and turn it on. It is simple to put the bends in those ends free hand over the very hot blanket. You will want to use two pieces of wood to push with to avoid burning yourself. |

Now clamp them together to hold the oval shape and let them sit until assembly time. That is the next step, attaching them to the prepared necks and tops. They are first glued at the edges, and then secured with tentalones. Stay tuned, you will see that in the next day or two.