There is always an element of tension in the bending of sides. but I think I am developing a pretty good system. Got all six sides bent today without problems.

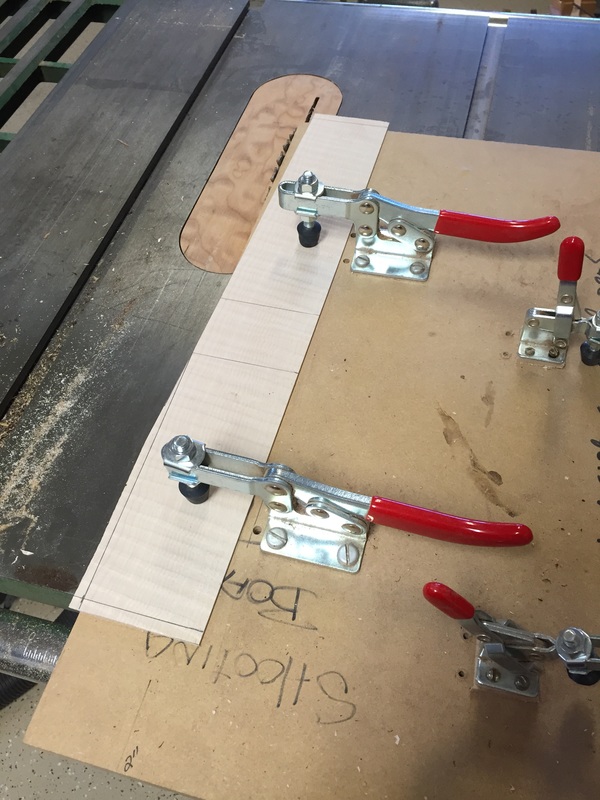

First I cut the sides to their proper shape using this shooting board with clamps. It rides in the twin slots of the table saw.

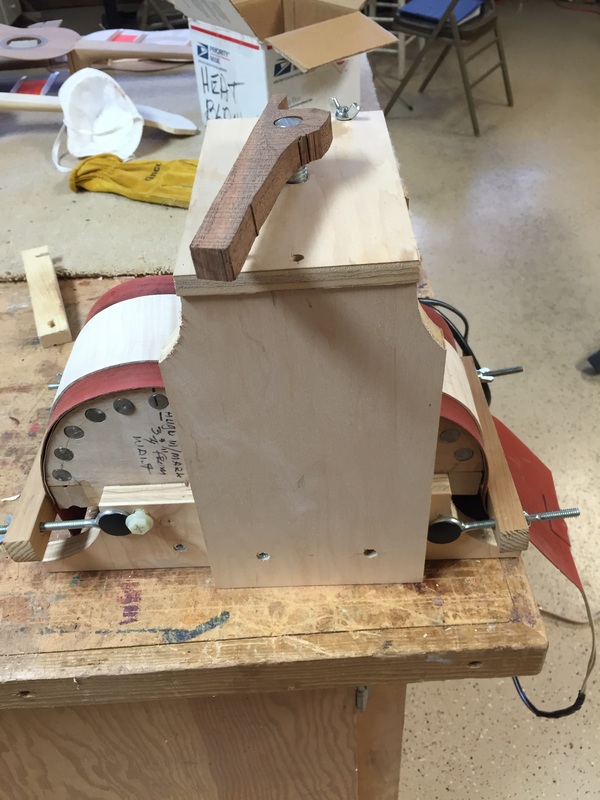

Then I set up my home made bending press laying on it the heat blanket which is connected to the blue voltage regulator shown. I turn it up to high and put the very accurate thermometer on and let it rise in temp to 300. While the temp is rising I spritz the side to be bent with water and put the top on my bending machine. When the temp hits 300 I slip the wood under the "guillotine" and let it heat up as the temp rises to 350. At that point I switch the volt regulator to "variable" and it seems to hold the temp there. Then I begin to screw down the "Guillotine" slowly to make that first critical bend of the waist.

Once the waist is bent I slowly bend each side down and clamp them as shown. I let the side cook for about five minutes and then turn the heat off and let everything cool down. When I can put my hand comfortably on the heat blanket I undo everything and take the bent side out.

The still hot side is put in this press to cool while I get started on the next side.

| I saved the East Indian Rosewood for last as it is lovely and kind of pricey. I wanted to practice on the more common wood. | Success ! it bent beautifully and here are the two sides cooling in the press. I also bent sides of Cumuru. It bent slowly but well. A pleasant surprise. Also two sides of tiger stripe maple , always tough to bend, got a tiny crack in one side but it is usable and fixable. The undulating grain makes curly maple always a challenge to bend. |