A fruitful afternoon in the workshop. I got a good start on #s 129 and #130 sanding the backs down to .080, their final thickness, and likewise finishing the soundboards.

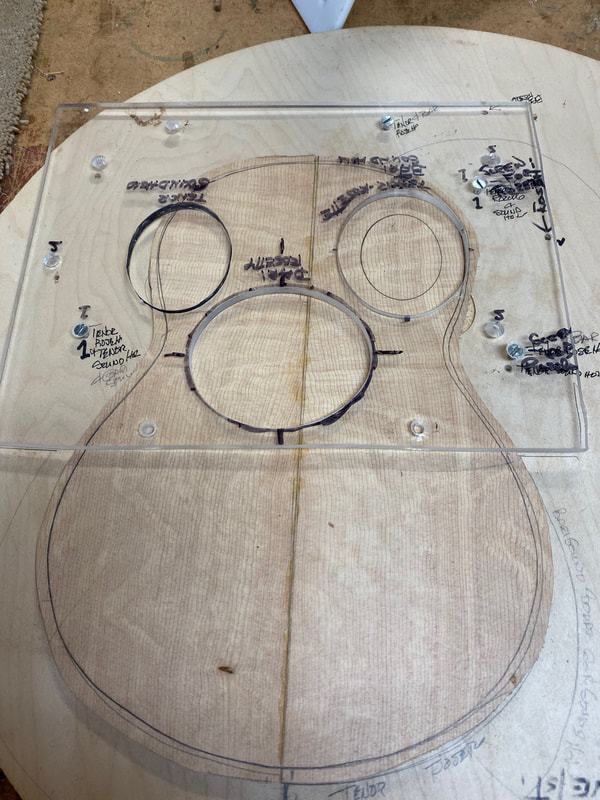

Heres the set up for cutting the groove around the sound hole. The router guide will ride around the plexiglass oval.

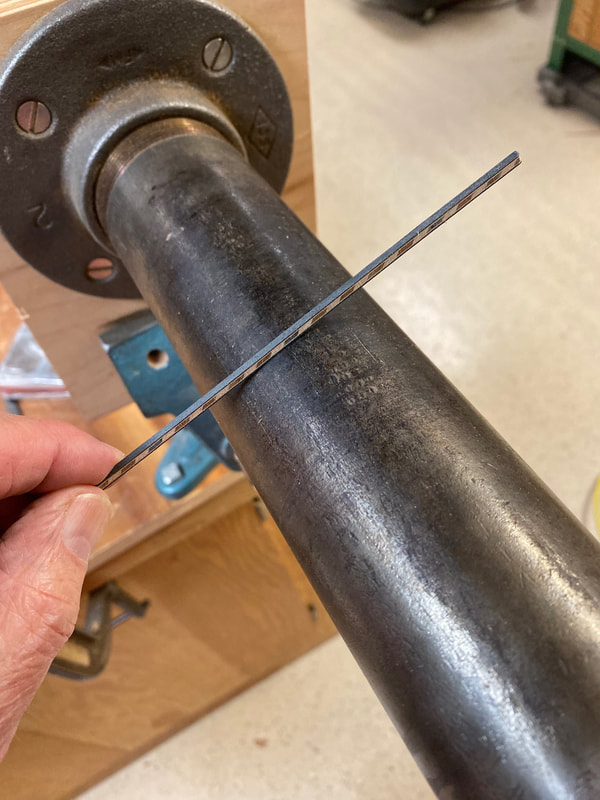

Yes, its old fashioned, but I find it more successful to cut the oval sound hole this way. A rough hole to slip over the reciprocal sander tube, and then sand out the rest of the oval hole.

Then you heat up the hot pipe to bend the "Rope" to fit in that groove you just cut.

Success- a couple of good fits, and then a little thin super glue to cement them in and it will be time for the thickness sander.

Sanded down to it's final thickness this soundboard of wild Bear Claw Sitka Spruce is ready to get it's bracing. This will be spectacular when finished. A great piece of Bear claw.

Here is it's Bubinga back, This is lovely wood.

And here is the front and back of #129, Nice East Indian Rosewood and an unusual top of Redwood with some interesting figure. Ought to be striking when finished and sure to sound great.