Yesterday I sold the first Baritone I had made back in 2011. It has been a wonderful instrument, but from the beginning, the lower left corner of the bridge was a bit separated from the soundboard. It did'nt effect the sound nor the playing so I never fixed it, but I just did'nt feel right sending it to it's new owner with that blemish. So today I addressed taking off the bridge and re glueing it. Not a simple task.

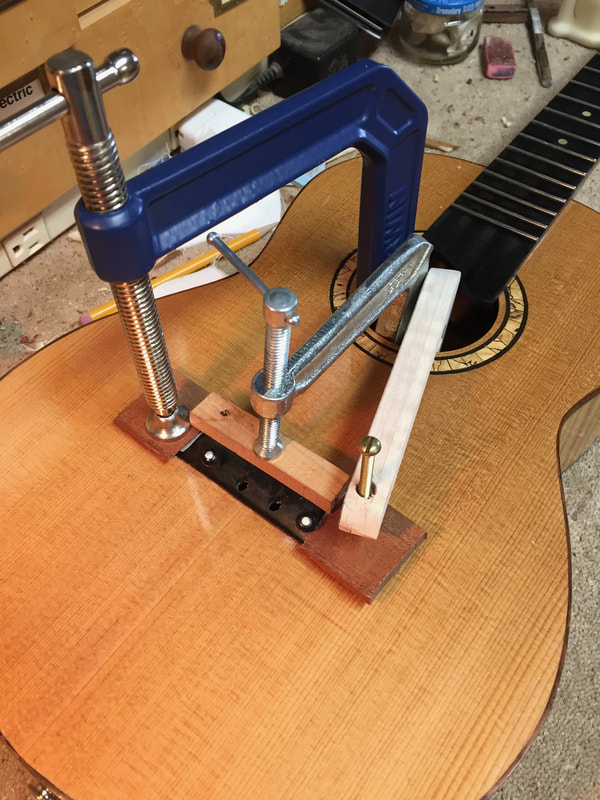

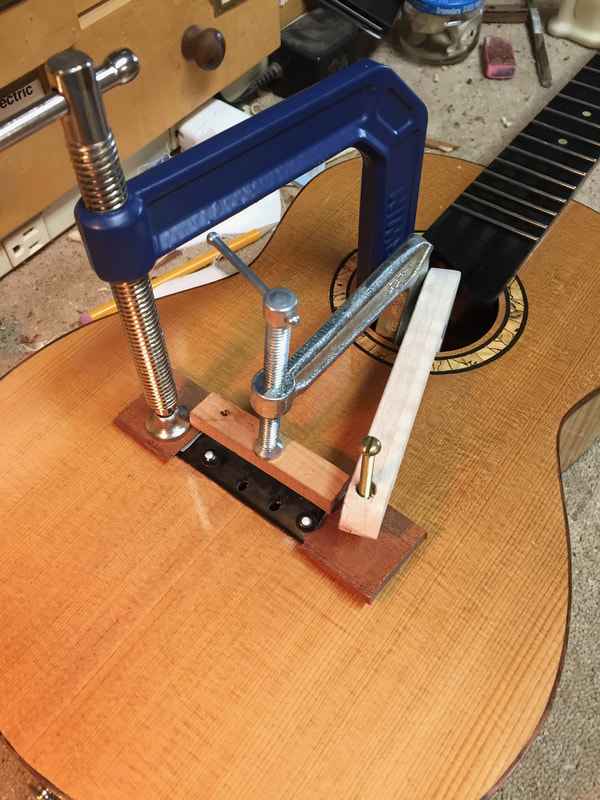

Here is what it looks like it at this moment. Removed, cleaned up, re-glued and firmly clamped down as the glue sets. After dinner I will remove the clamps, do a bit of refinishing on the bridge and tomorrow string it up ready to deliver to its new owner. I am so pleased as this was a highly successful fix.

To remove a bridge you must heat the glue under it to a soft state that will allow you to pry it off. I put the shop iron upside down in a vise to heat up the aluminum block devise to transfer heat to the bridge.

Using this handy little thermometer I let the tool get up to 250 degrees before applying it to the ebony bridge. I takes a while to get wood hot enough to melt glue.

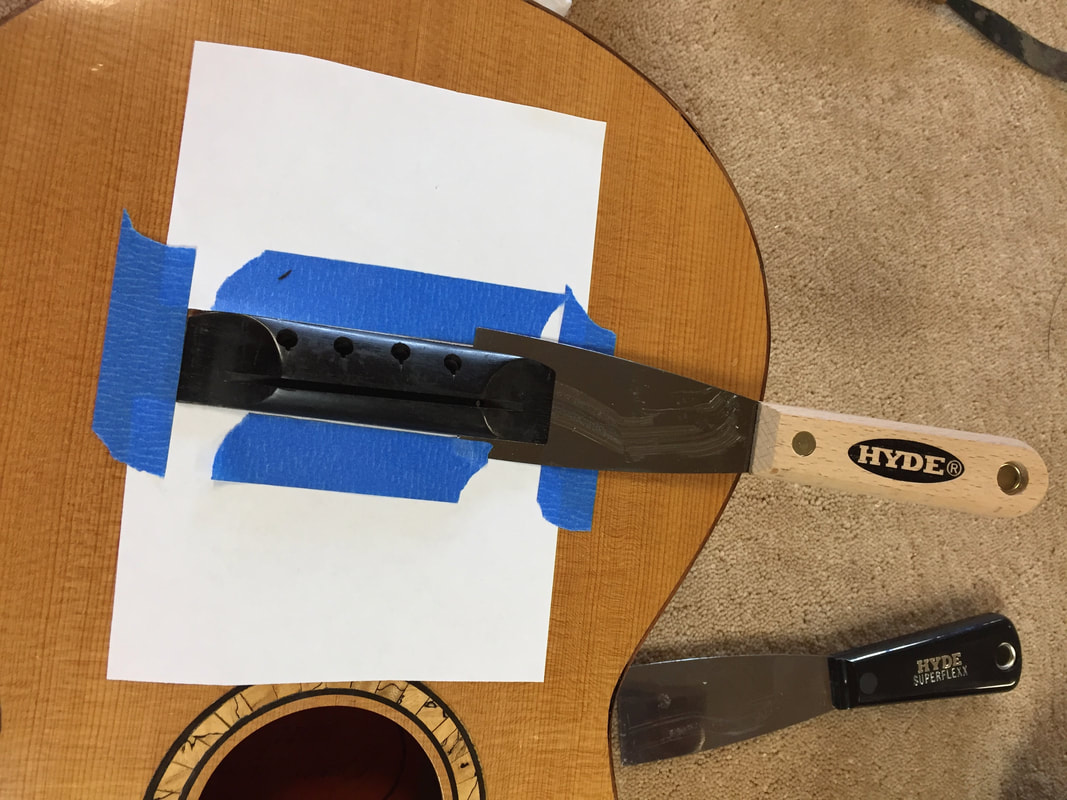

Protecting the top and its finish with paper and tape, I began to inch the thin flexible putty knife under the bridge. Very slowly heating the wood and wiggling the knife I made progress separating the ebony bridge from the spruce top.

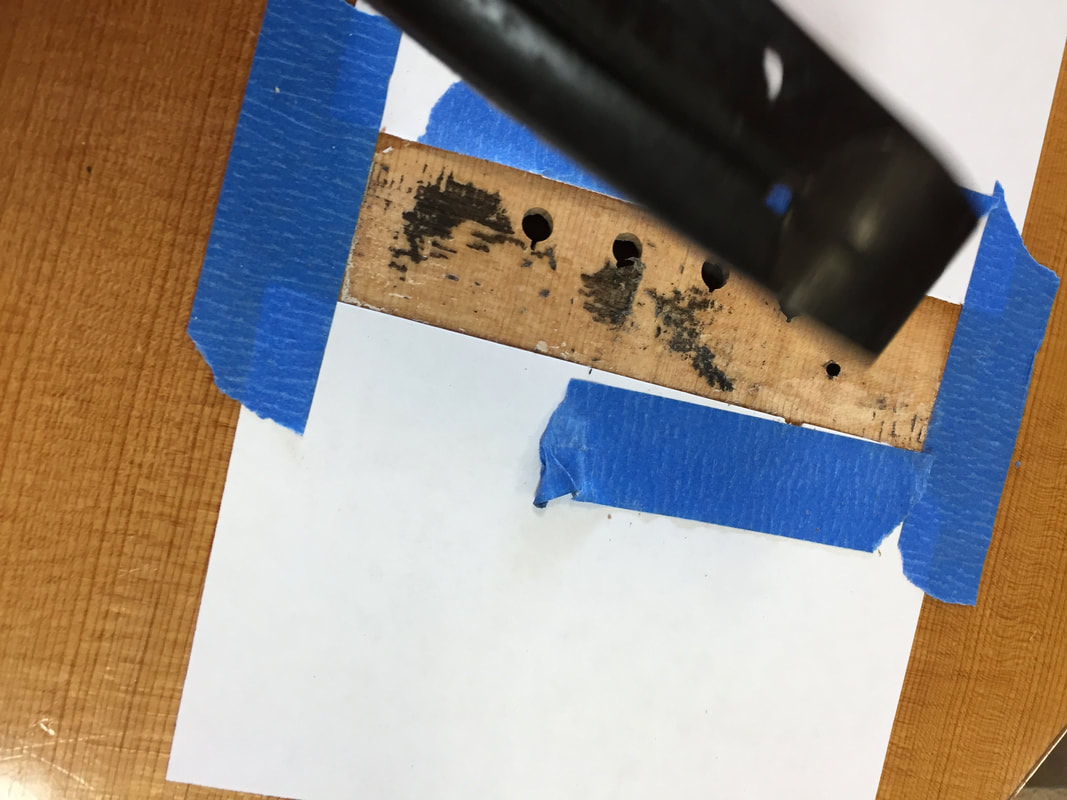

It took thirty minutes of careful work, wiggling the knife, heating the wood, moving the knife further and further , Until finally the bridge popped off. Success ! no damage to the spruce, Complete separation, and now I could see why the initial problem. I had probably not clamped one corner of the bridge adequately in 2011.

So now it is just a simple matter of scraping the top and the bridge clean of any old glue, and re attaching the bridge to it's proper place. Problem solved. Took a while, and a lot of thought, but feels real good to be able to send this lovely baritone to its new owner without a defect.