We had a rainy Memorial Day, a perfect day to launch a new project in the shop. I started three new Concert Pinecones and had a bit of a head start with previously roughed out necks, cut out maple backs and bend ready maple sides, but I really got a great start today

| I started flattening the tops of the necks using the disc sander first, then finishing up on the belt sander. These necks had been just roughed out on the bandsaw. I have a vacuum system attachment that removes all of the sawdust. This would be a very dusty operation without that vacuum. Next I marked out the Englemann Spruce tops and sawed them out on the bandsaw. They need to be smoothed up a bit and a couple of passes through the sander does that nicely. | Now, while they are still thick, I like to cut the sound hole. I use this fly cutter in the drill press. does a nice job. |

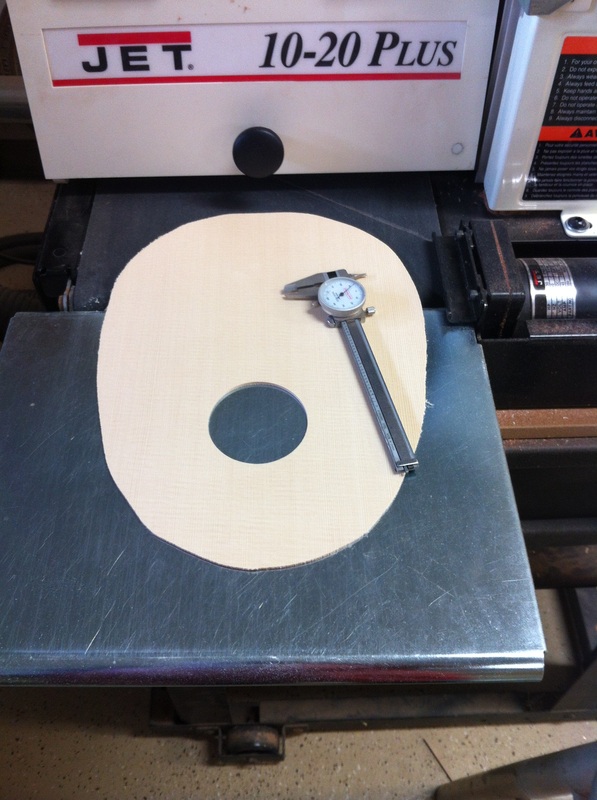

Now it is time to thin the tops down. I took them down to 85. This is beautiful Englemann and ought to make these ukes sing sweetly.

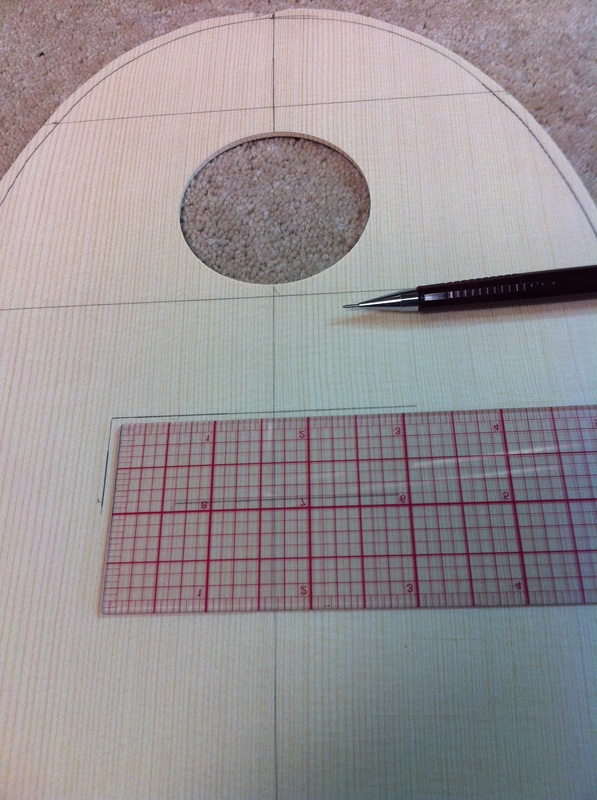

| Look at this beautiful wood. extremely fine grain Englemann Spruce, really highly figured maple. In the right hand picture I am marking out the center line, the brace locations, etc. I find that a fine point pencil and a transparent plastic ruler are really handy in this endeavor. These markings are all on the underside of the tone board and will mostly be covered by braces etc. that will be glued on top of them. Pencil marks are very hard to eliminate so take care to not make them on any part that will be visible later. |

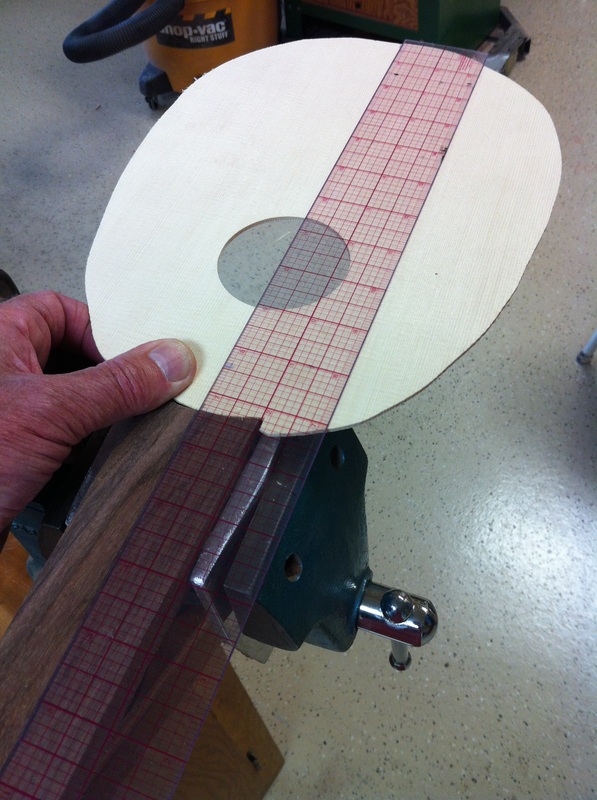

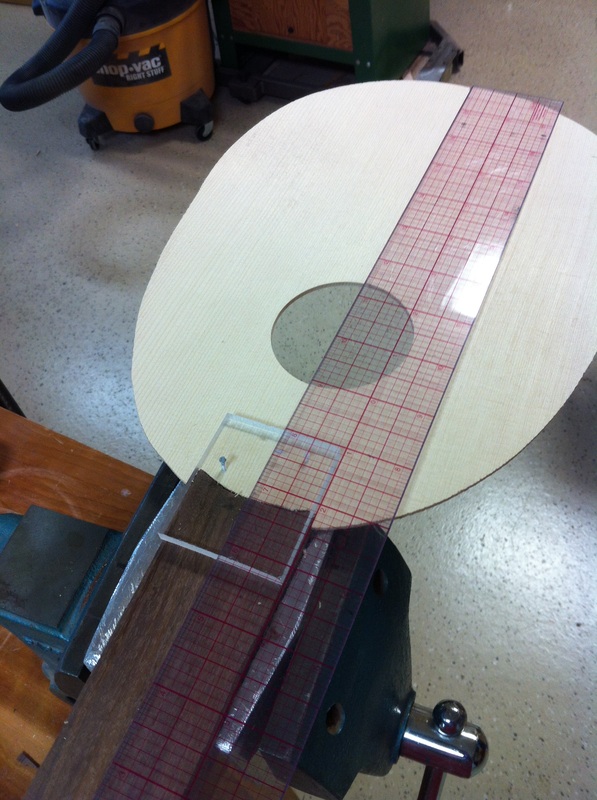

| Now it is time to work on the necks. Here are the marking on the underside showing the cuts I will make to accept the sides. I have nibbled away a step-down on the top of the neck to perfectly fit the top to. Now I am checking to be sure the top is lined up straight with the neck. For this you need center marks on the top as well as a centerline running up the neck | The bandsaw is the ideal tool to cut these slots. The top of the neck is now perfectly flat. that allows these cuts to be accurate and exactly 90 degrees from the top. It is vitally important that the neck and the body are in exact alignment. Once you have them aligned I nail them in their positions using this plastic caul. The caul and the little nails will allow me to put them back in this exact position when I had applied glue. |

In the waning minutes of this busy day I sawed, carved and sanded out the six braces that I will be using. Sitka spruce with its fine grain rising straight up for maximum stiffness and strength. I saved a bit of whittling time by sawing the narrowed ends on the bandsaw. Tomorrow I start shaping the necks.