The Butt plates got shaped and glued to the soundboards.

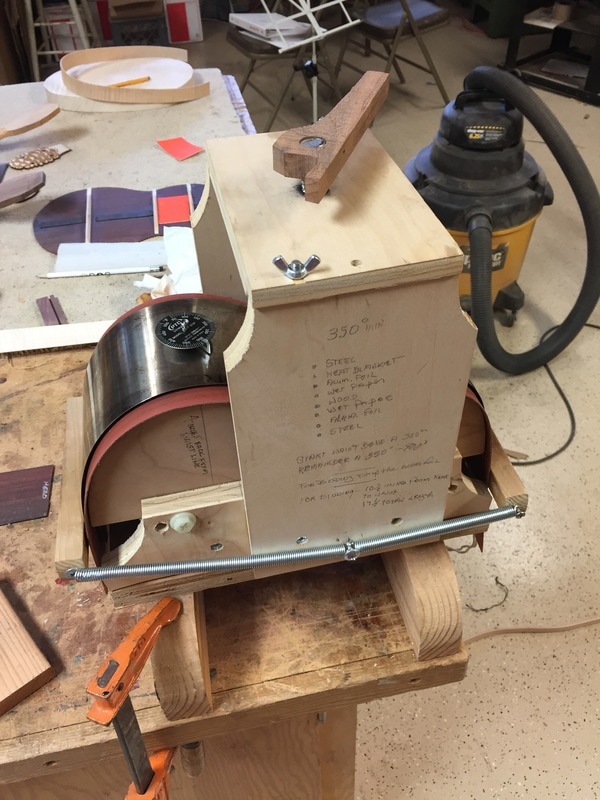

Now it is time to bend the sides in my homemade bender. It is loaded with the first Cocobolo tenor side. Cross your fingers folks, this is a lovely piece of wood that I would hate to break. When the heat got up to 300 I slowly began to bend the waist.

By the time it got to 350, the waist was mostly bent and then I slowly lowered the sides. When they were all the way bent, I completed tightening the waist screw. I didn't hear any cracking sounds, Lets let it cool now and see what we have got.

Hey !, it is looking good. This sandwich of wet paper surrounded by aluminum foil shows no cracks or breaks- lets un-wrap it.

Just look at the oil that has seeped out of this Cocobolo, but it is still looking good, lets get the paper off and find out for sure.

Oh Man !- It is perfect. A great bend of this extremely dense and tough wood. Lets hope the next side goes as well.

It Did !- Two perfect sides. This is the third Cocobolo ukulele that I have made and I am beginning to conclude that this wood is pretty easy to bend. Maybe the extreme oiliness of it has something to do with that. It will take some sanding to get the surface oil now baked on, cleaned up- but then the wood will show it's beauty once again.

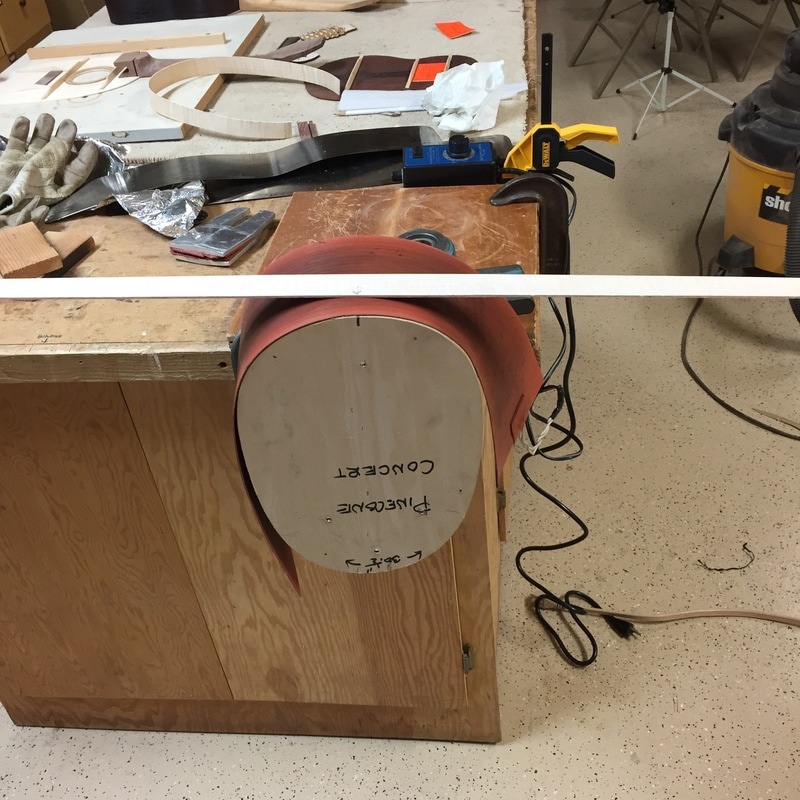

Now for the Pinecone side. This is an easy one, Once long strip of figured maple that gets bent in an easy oval. I just lay the heat blanket over the wooden form and get the blanket up to 300 plus degrees- spritz the wood with a little water and gently begin to bend the big bottom bend.

Once the bottom gets its bend the mold is turned over in order to make the sharper bends at the top. This is a little harder to do simply because the bend must be sharper, but still quite easy.

And the Tenor Pinecone has it's sides. I will just leave it this way over night. Tomorrow it will be a simple matter to trim a bit off the ends and glue it on the soundboard.