The challenge was to bend thick purfling into a tight oval that would be the decoration around the sound hole of my second Kasha ukulele. I had used it on #100 the first one, but the bend was not perfect. How to make it perfect???

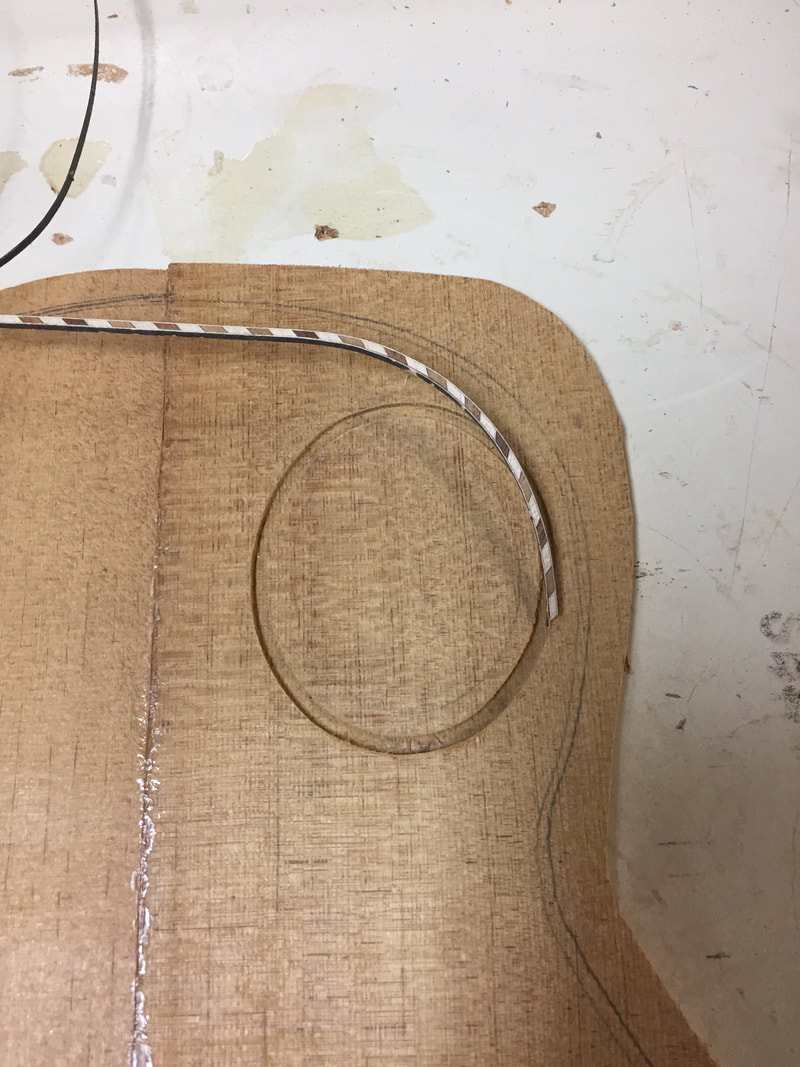

Here is the challenge. I had cut the oval groove to accept the purfling, but this stuff is stiff. How to bend it in a continuous smooth bend, without breaking it?

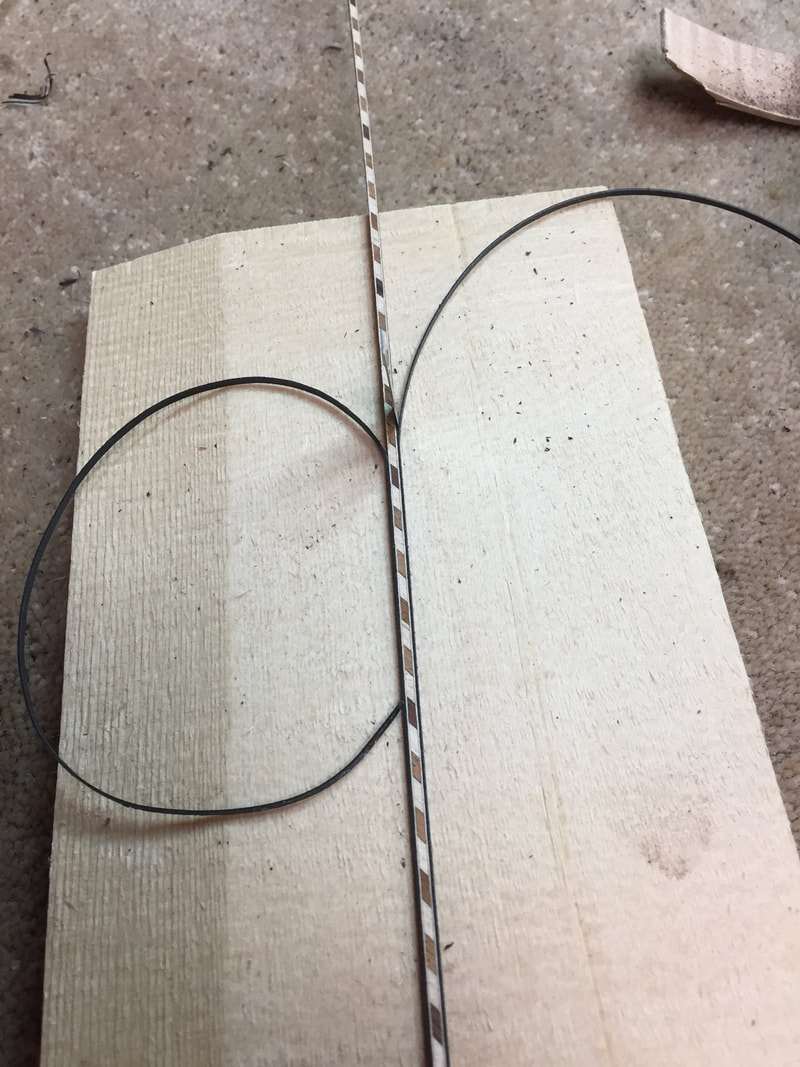

I had been advised on a You Tube post to split away the black fabric by heating it with a hot air gun and running it past an exacto blade pounded into a piece of wood-so I did that.

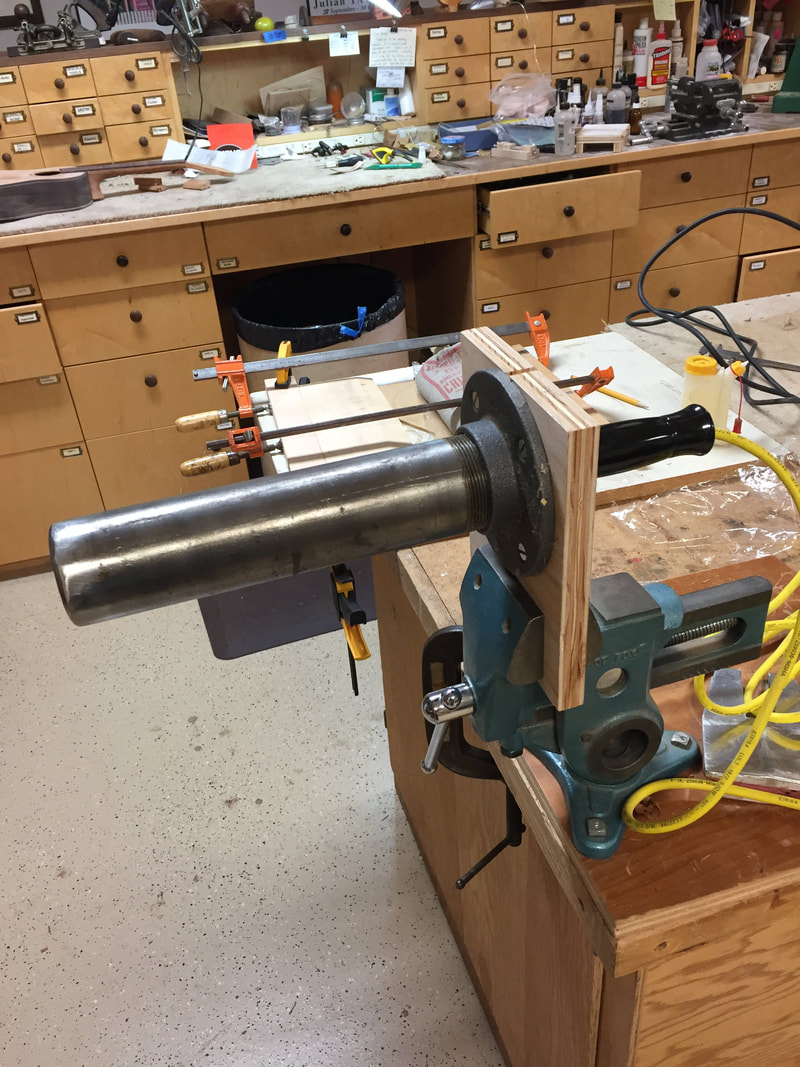

I applied heat to the purfling with this bending iron made of a steel pipe and pipe flange which contains a commercial soldering iron. It takes a while for the iron to heat to bending temperature but I got it up to 300 degrees in perhaps 15 minutes..

I had trouble handling the split purfling, so I tried bending the complete purfling and found that it worked quite well. I was able to make a smooth bend of this tight oval and insert it into the channel I had cut.

Before applying the super glue, I gave the channel a good dose of shellac and waited for it to dry before inserting and glueing in the purfling. That is done to prevent the superglue from soaking into the wood and staining it.

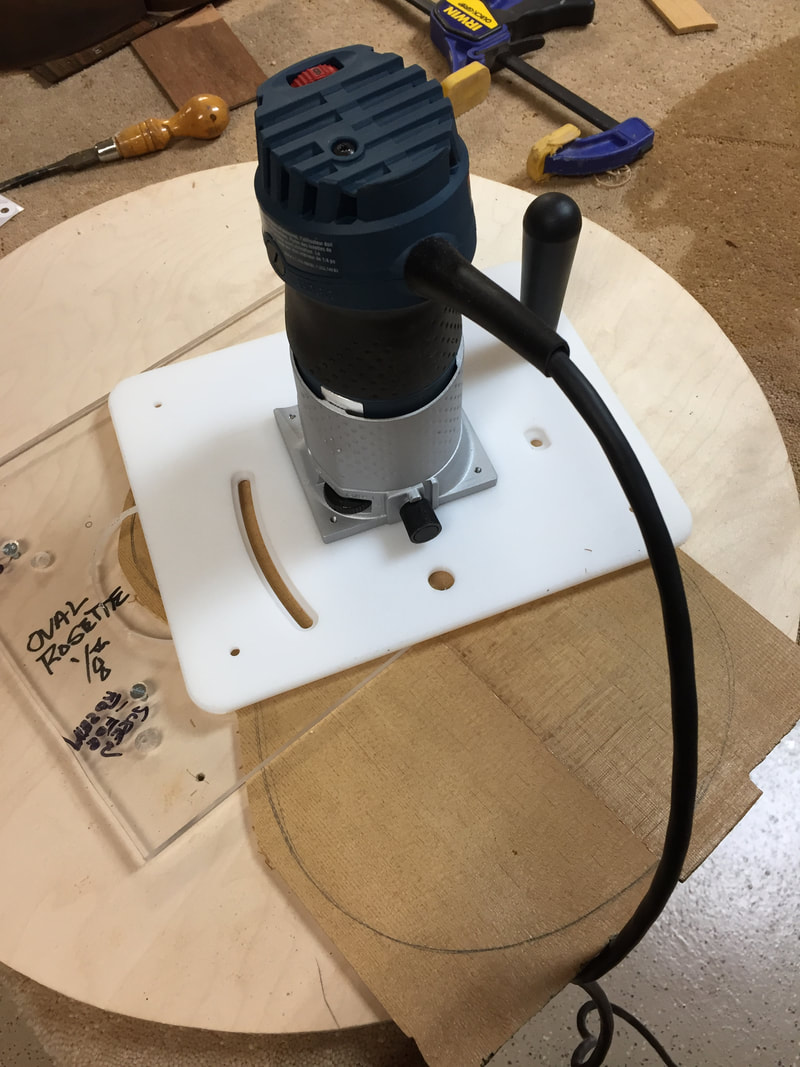

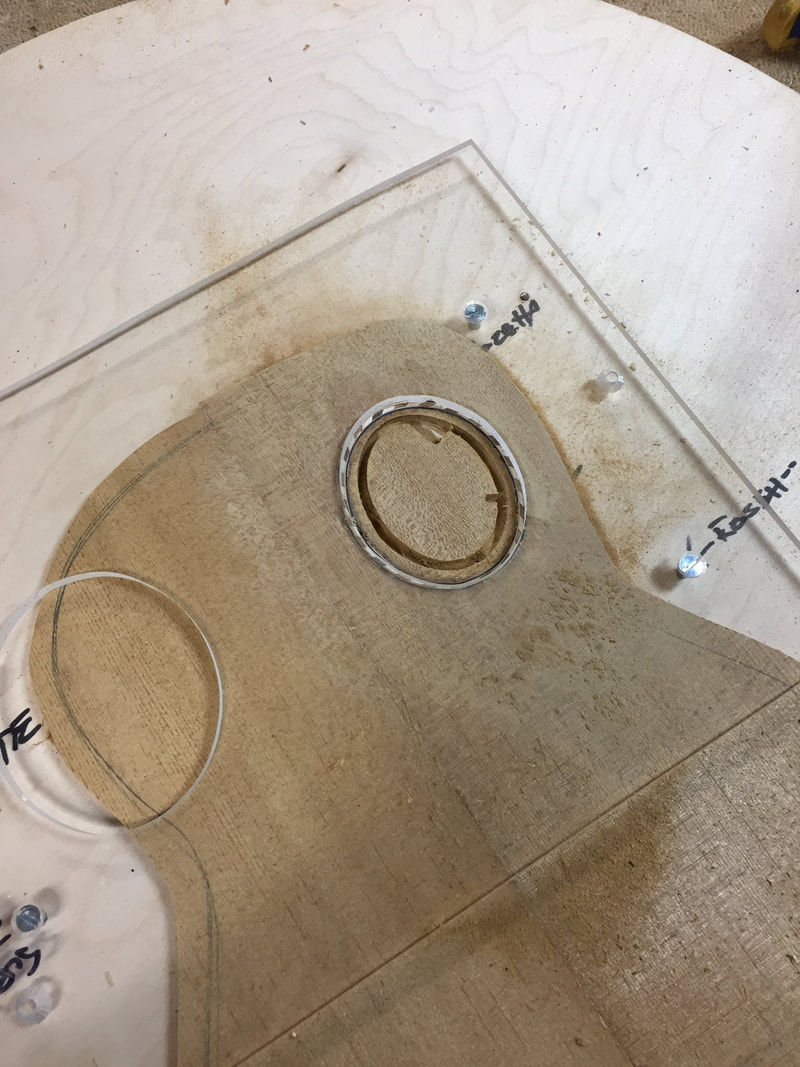

Once the glue had dried on the rosette It was time to cut out the sound hole. Here the acrylic plate is carefully set over the rosette and screwed down. the top is held firmly in place ready for the router.

Here is the router, in place and ready to cut out the sound hole. The cutting bit has been lowered to just about cut through the spruce top.

And here is the cut. The sound hole is almost cut free.

It was so close to being cut through that I was able to punch it out. Once this top is run through the thickness sander to the desired thickness this top will look very good.

And this newly bent rosette will be handsome and nicely ovoid. Who says old dogs can't learn new tricks.