TODAY, AT LAST, I got back to the workshop after a few intense days working on the book. I have begun a new build. Three tenors, all with Watertank Redwood tops.

A new build always begins with the mundane. I needed to put new sandpaper on the thickness sander to get the selected wood down to workable thicknesses and of course to get it cleared of saw marks, stains and see what i really had to work with. I put 100 grit on the machine to cut fast and deep. Here I am cutting new strips from a roll, copying the successful sand paper that had been on the machine but worn out.

First I sanded the East Indian Rosewood, back and sides. This uke is going to be for me. Beautiful wood. I will glue the back together tomorrow and then sand it down to about .80, I sanded the sides down to .75 which is the thickness I will bend them at.

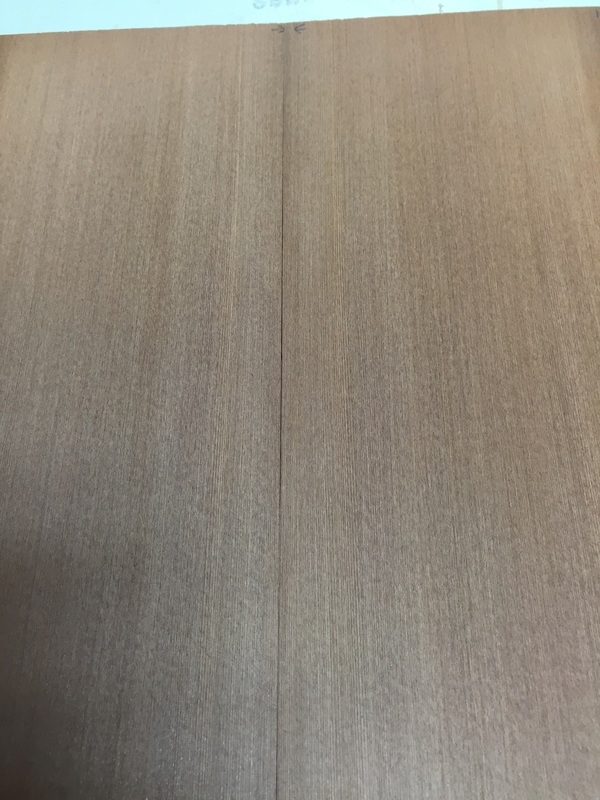

Next I sanded down the back pieces for the maple/redwood tenor for Brian H. You cannot see it in this picture but there will be lovely grain when this back is finished. I will glue it together and then sand it down to its proper thickness.

The third tenor will have back and sides of this beautiful Australian Blackwood that I have been hoarding for some time. This has wonderful figure and when finished it is quite spectacular. Here are the sides.

There is the back on the left, A one piece back. A great piece of wood

And here is the master grade redwood from the old NYC water tank that will be the top. I will set off these woods with a dark binding outlined with black/white/black purling. Should be stunning.

I am getting ready to glue together the two piece redwood back. I place a big old plane upside down in my bench vice. Here I am straightening out the edges to get a good glue joint.

This is looking pretty good, but not good enough.

. To get that joint so tight you cannot see light through it I take it to the table saw,

that flat saw table with a piece of sand paper laid on it will get you a perfect fit. Remember however, that you only sand in one direction. If you do not you develop a rocking motion and you will never get a perfect joint.

that flat saw table with a piece of sand paper laid on it will get you a perfect fit. Remember however, that you only sand in one direction. If you do not you develop a rocking motion and you will never get a perfect joint.

Now it is time to glue them together, Here is how I do it, crude but effective. The bag holds about twenty pounds of lead birdshot. It is mighty handing for holding things down.