I spent most of my time making parts from scraps, Bridge backing plates from scrap walnut, Bridges from small pieces of Honduran Rosewood too small for anything else. Nice to have that stuff pre-made when you need it.

Then I sliced up a nice chunk of Honduran Rosewood for fretboards on my next generation of Pinecones. I got six nice pieces and a chunk left over as seen above. After shaping them up on the planer, and sanding them level smooth and to the proper thickness with the sander I was ready to cut the fret slots. But first you must have the nut end at a perfect 90 degrees. Be sure to mark the nut end once you have squared it up on the table saw.

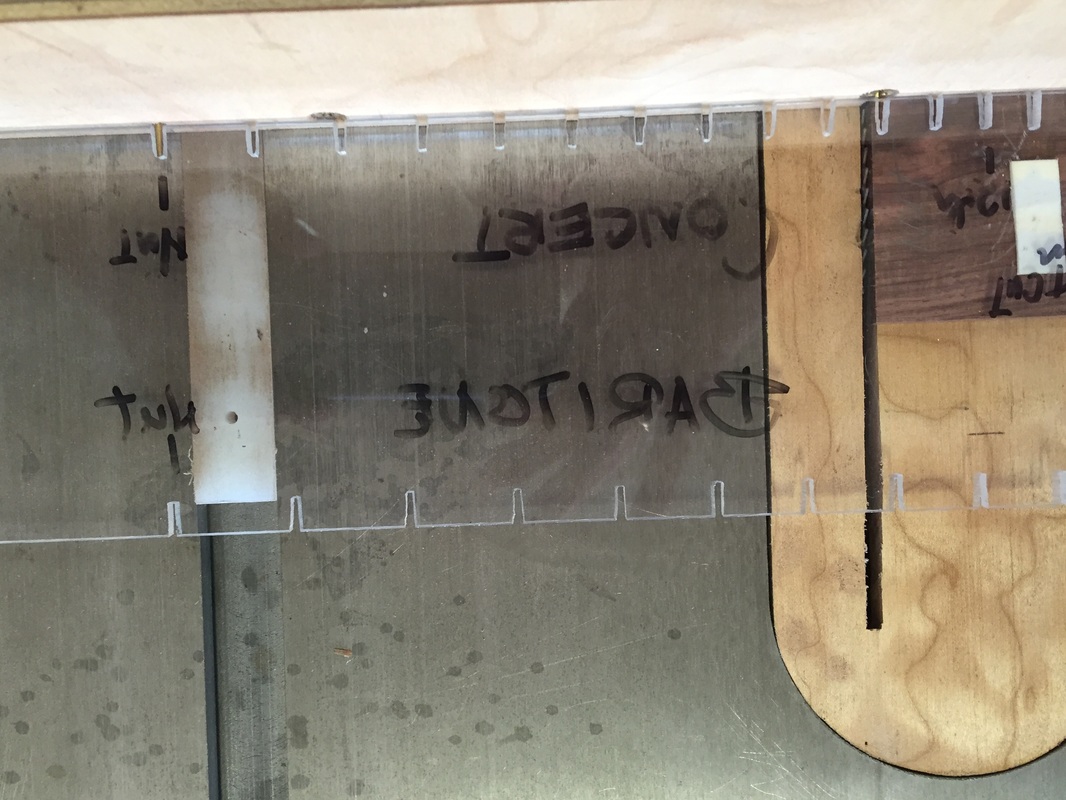

Double backed tape is stuck onto the fretboard which is resting tight against the protruding saw blade. The acrylic indexing jig will be set upon the tape holding the two together.

After passing through the saw blade 14 times, advancing the fretboard to the next slot each time, here is the result. A perfectly grooved fret board.

BUT BEWARE the next time my mind wandered and I taped the jig upside down and cut baritone fret slots. Had to toss that nice piece of Honduran rosewood. OUCH !

BUT BEWARE the next time my mind wandered and I taped the jig upside down and cut baritone fret slots. Had to toss that nice piece of Honduran rosewood. OUCH !

So I ended up with five Pinecone fretboards, Could have been worse. A good reminder to keep your mind on the task at hand.