This winter weather makes the workshop seem ideal. Got a lot done today. It began with the last coat of French Polish on these ukes while the hot pipe was heating up.

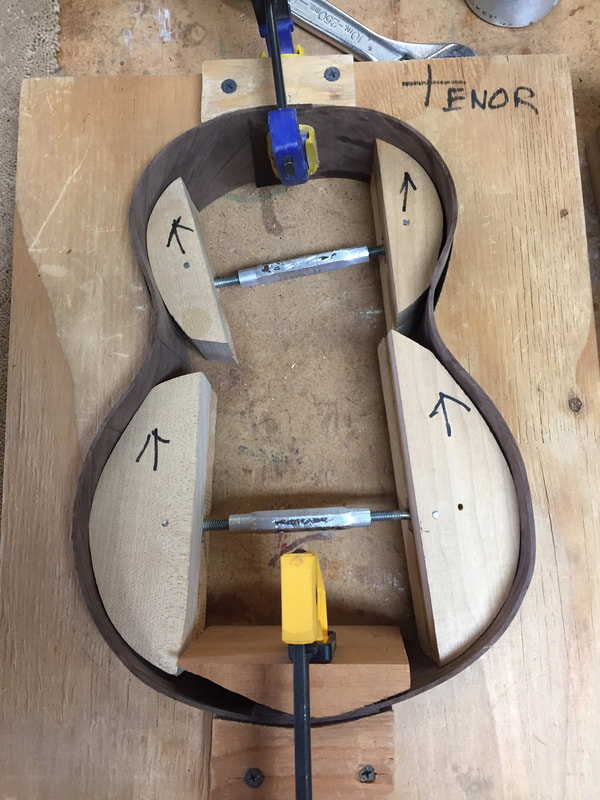

Took the Bubinga sides out of the mold. This is a beautiful bend, ready to be attached to the soundboard

Now the pipe was hot. I bent the East Indian rosewood sides and got them in the mold. It went well. East Indian is quite easy to bend despite some wonky grain. It wanted to twist. The mold will straighten that out.

While the iron was hot I decided to bend the bindings I will use on #14 and 15. They will be ready when needed.

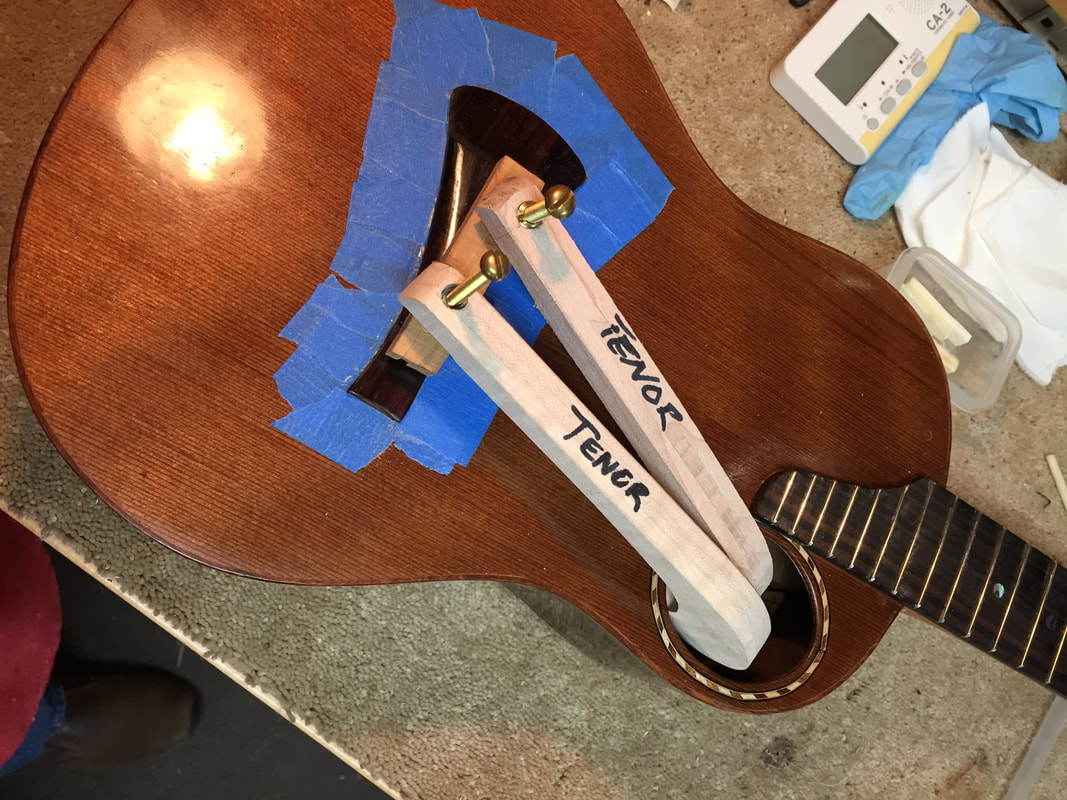

Then it was time to glue on the bridge. First I needed a saddle for the bridge. I have a piece of buffalo bone in the vise being shaped with a file.

Once that is fitted into the bridge it is time to get the bridge to its proper location. That is done with the use of this odd contraption.

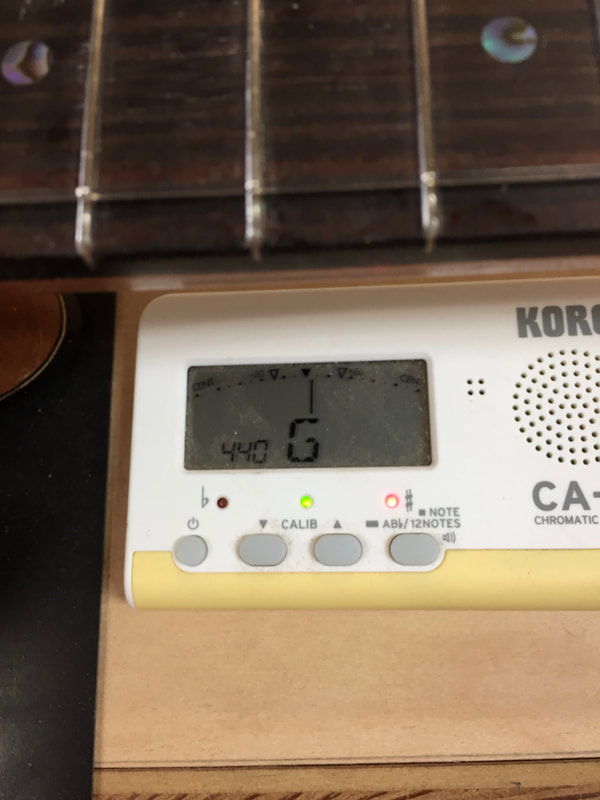

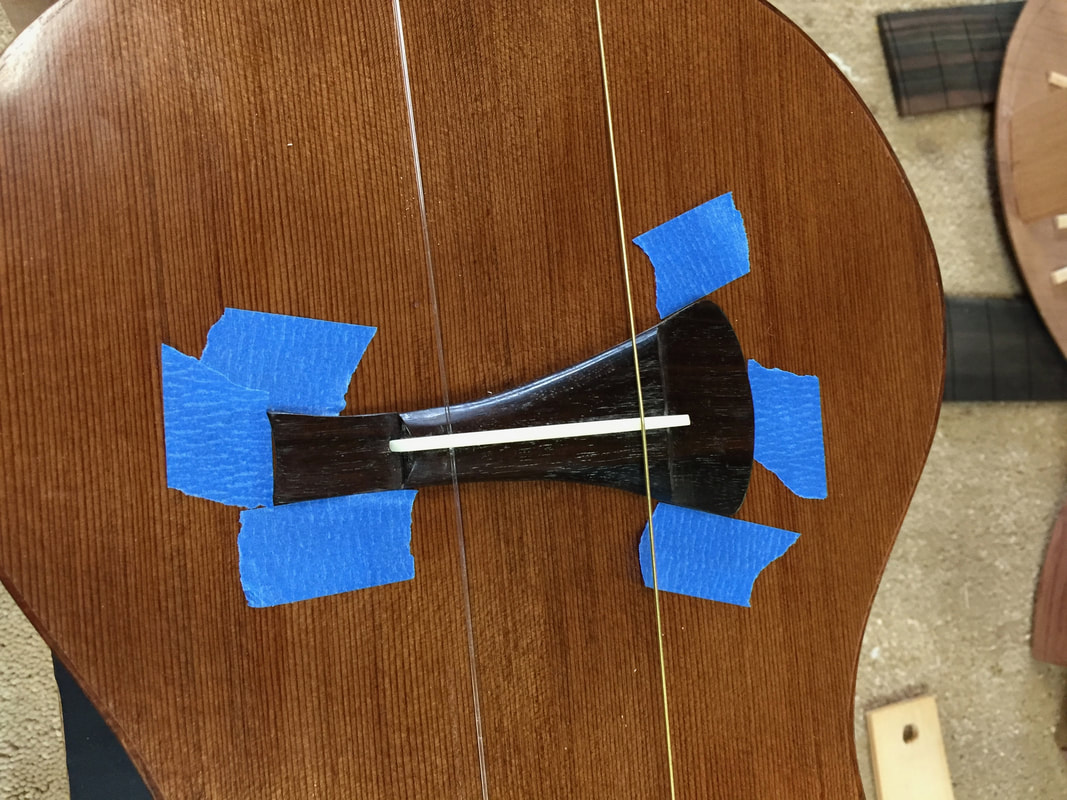

Two strings are stretched across the instrument from saddle to zero fret. The strings are tuned to any note recorded on the Korb tuner. Then each string is fretted the 12th fret. If the note is exactly the same as the unfretted note you know the saddle is just right. If not you move the bridge and saddle until the notes match. Do this with both strings and you have the proper position for the bridge. Mark the spot with blue tape and proceed.

Once the notes match, blue tape records the perfect place.

now surround the bridge with blue tape and scrape off the shellac underneath it with a razor blade.

Glue it and clamp it and tomorrow morning we can string this uke up.