THE BEND BEGINS with a quick spritzing of water from the spray can

Then to the mold form held in the vise. The heat blanket is laid across the broad end of the form and heated to a max of 350 degrees. The little thermometer sitting atop it is worth its weight in gold. When the temp gets to 350 I turn it down.

Center the side piece on the heat pad and begin with a gentle rocking motion heating both sides of the wood. Soon it begins to sag and bend itself around the curve. Slowly and gently bend it around the form. wear leather gloves so you can get right into it without burning your fingers. It just takes a few minutes and----

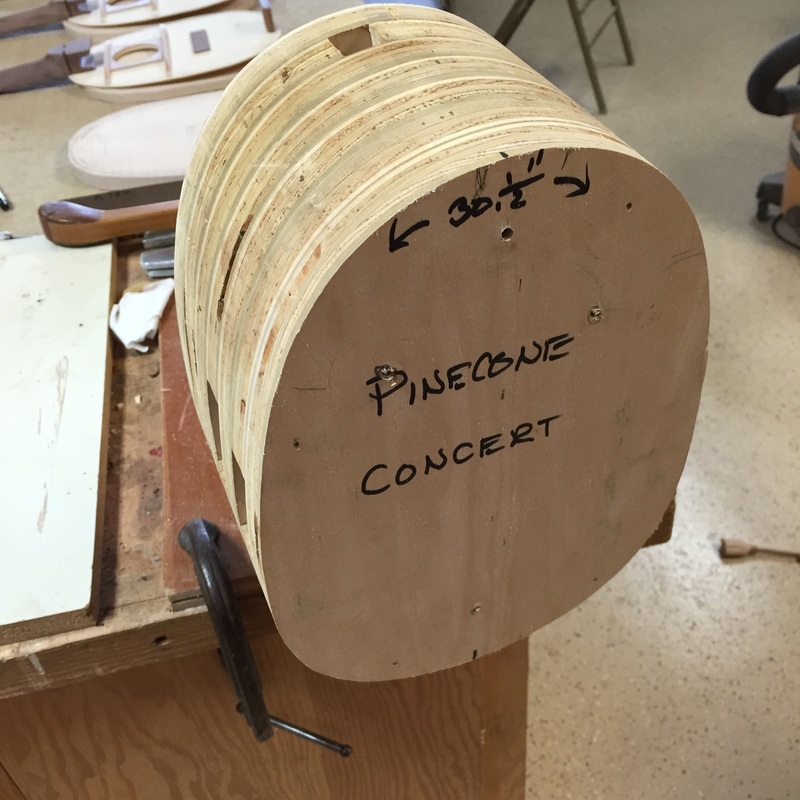

then you want to turn the form over to access the sharper angles of the top of the uke. I bent all five of the sides on the wider bottom side before turning the form over to make the tighter curves where the sides will have to fit into the slots cut in the neck.

Now we work at making the tight bend at the top. I have found it helpful to rub this part of the bend with a flat piece of wood. Seems to make the side want to bend.

With the sides bent, the fun part begins- fitting the sides to the top and glueing them onto it. Tomorrow's blog will show that exciting time.

With the sides bent, the fun part begins- fitting the sides to the top and glueing them onto it. Tomorrow's blog will show that exciting time.