Bending sides is always traumatic. It is so easy to break them, and there is always a bit of a mystery of how best to do it. Each wood is different, Some bend readily, some are very tough. Walnut happens to be an easy bender. I took it on first. Next are Brazilian Rosewood and Cocobolo, two woods I have little and no experience with.

Here is my technique.

Here is my technique.

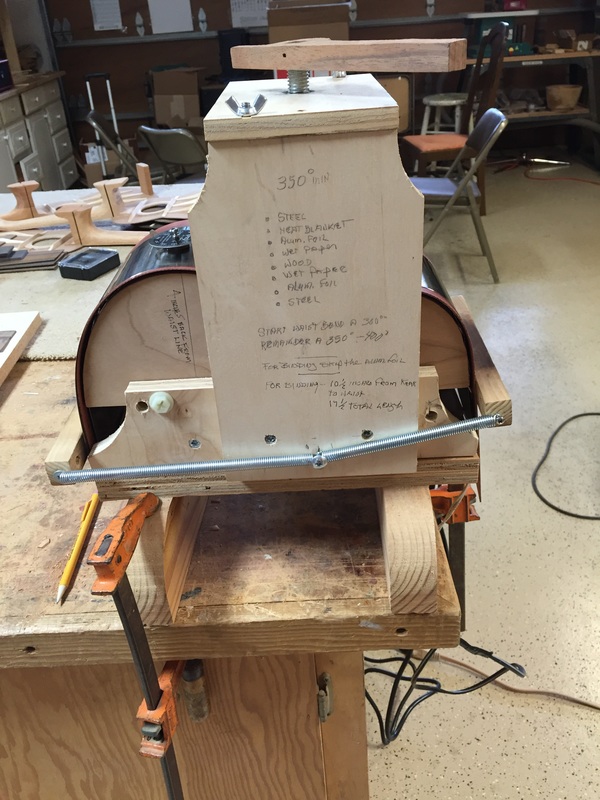

Here is my bending machine. Now loaded with the first of the walnut sides. You may be able to read my recipe on the side. First a steel bending sheet, then a sandwich of wet wood, parchment paper, wrapped in aluminum foil. Then the heat blanket topped with one more steel sheet to contain the heat.

Here is the end of the press and shows the control device which I use to turn on and off and reduce the temp from time to time. The heat blanket plugs into it.

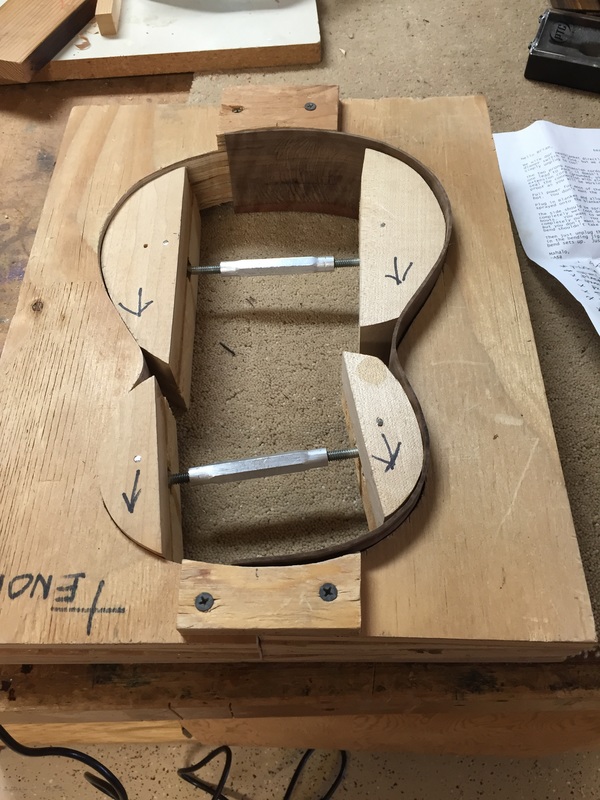

Once you wrap the side up into this package it is difficult to remember up from down. It is important to mark the sandwich up. Note the marks on the left which line up in the bender, and on the right, an upwards arrow indicating how it must be put into the bender.

Now it is bending time. When wood gets to this temp it is ready to bend. The lignin in wood gets fluid and wood is bendable. When it cools it stiffens again in the new position.

Hot out of the press, It doesn't get any better than this. This is a perfect bend. When I peeled off the foil and the paper, the wood was perfect. Wow! that is fun.

Now both sides are bent and in the form. A successful bend. Lets hope the Brazilian and Cocobolo will go as well.

While waiting for the bends to cool I was able to taper and form the fret boards to their final shape. They will of course be finally shaped in the final sanding after they are installed.