Some days ya don't

The day began with the tentalones attached to the entire top. When the glue dried I was able to prepare for the tentalones on the back edge.

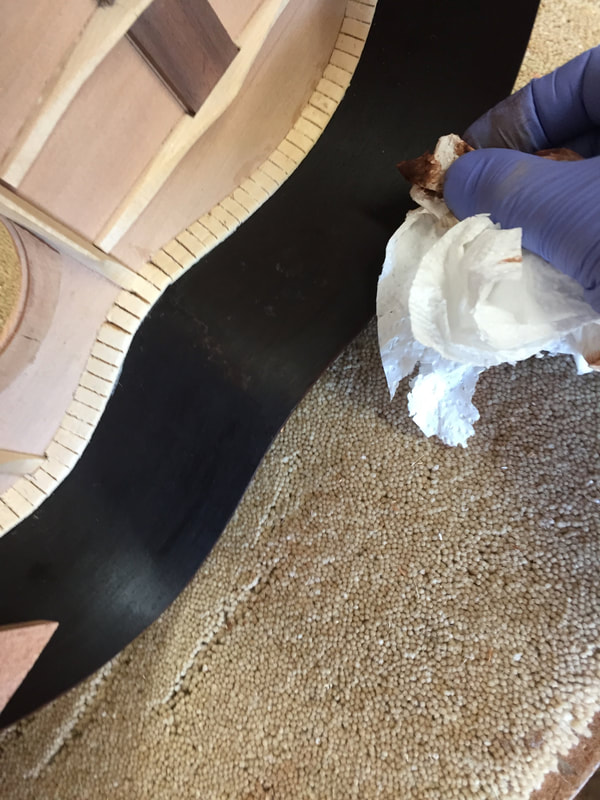

'that involved rubbing the area to be glued with acetone. This removes some of the oil from the wood allowing the glue to penetrate. Notice the red stain on the paper towel. that is oil from the wood.

And now the tentalones are glued on and clamped in place with clothespins beefed up with rubber bands to give them more grip. Not anything more to do on the tenor while this dries so I shall shift to the next instrument. #98.

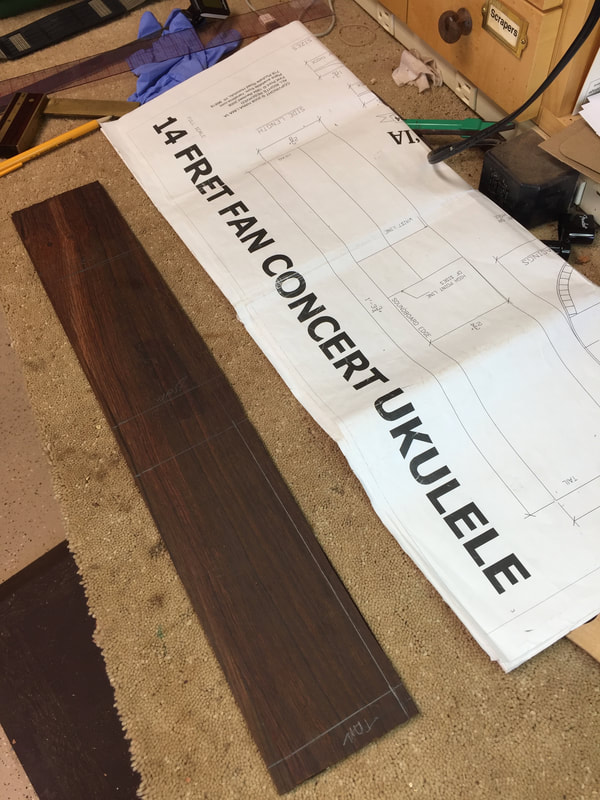

The next ukes will be a concert ordered by a nice woman who has name it. It will be called "Journey" What a nice name for an instrument that hopefully will advance her journey through life. I want to make this a special instrument. It will have Cocobolo back and sides and a Western Red Cedar soundboard. a Honduran Mahogany neck and matching binding. I bent the sides a couple of days ago but was not satisfied with the results.

One of the sides I bent had an interesting grain configuration that messed up the bend. The odd grain caused the lower bout to bend in an uneven way. I might have been able to sand it out, but figured "Journey" required perfection, so I decided to bend a couple more sides.

Here are the new sides being cut to shape. you can see the pencil marks guiding the saw cuts.

And here is the final cut.

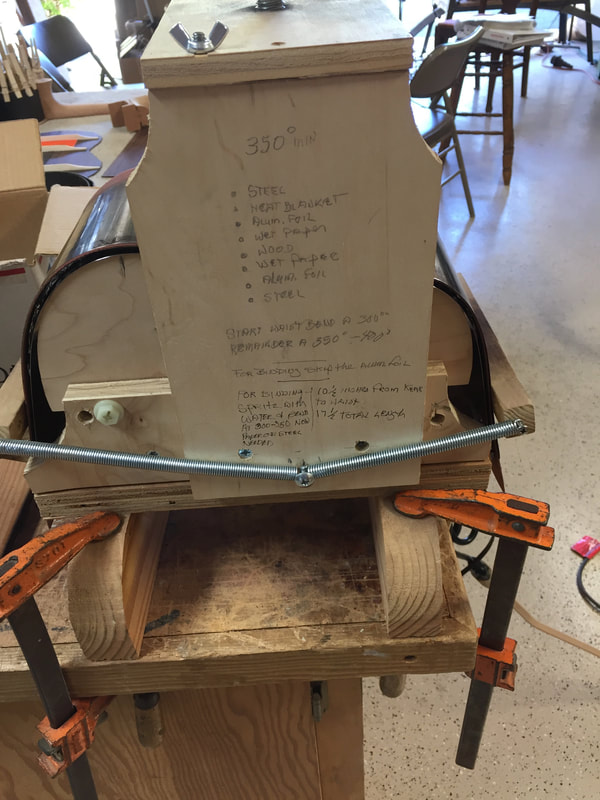

Here you see the roughed in neck, the sides and the yet to be joined back of "Journey" so lets get at it and bend the new sides. The wood is cut to shape, wrapped in paper, spritzed with water, wrapped with aluminum foil and place in the bender.

And now the bend is done. Hopefully successfully. The temperature got up to almost 400 degrees. then the heat is turned off and the wood cools in the binder. When it gets down to about 100 degrees I will remove it.and see what we have got.

And it was perfect. It was one of those good days when everything worked, When ya got it.